-

![Halocarbon 400 Oil [Poly(chlorotrifluoroethylene)]](https://www.polysciences.com/media/catalog/product/cache/41caa8e834a03fb3ab31ba2c24269124/2/5/25074.jpg) Halocarbon 400 Oil [Poly(chlorotrifluoroethylene), 400 centistokes]Catalog Number 25074

Halocarbon 400 Oil [Poly(chlorotrifluoroethylene), 400 centistokes]Catalog Number 25074Inert, non-flammable lubricating oil. Polymer is a blend of oligomers. Also used as an inert medium in transgenic studies of fruit fly Drosophilia embryos.

-

![Halocarbon 700 Oil [Poly(chlorotrifluoroethylene)]](https://www.polysciences.com/media/catalog/product/cache/41caa8e834a03fb3ab31ba2c24269124/2/5/25075.jpg) Halocarbon 700 Oil [Poly(chlorotrifluoroethylene), 700 centistokes]Catalog Number 25075

Halocarbon 700 Oil [Poly(chlorotrifluoroethylene), 700 centistokes]Catalog Number 25075Inert, non-flammable lubricating oil. Polymer is a blend of oligomers.

Also used as an inert medium in transgenic studies of fruit fly Drosophilia embryos.

-

![Halocarbon 1000N Oil [Poly(chlorotrifluoroethylene)]](https://www.polysciences.com/media/catalog/product/cache/41caa8e834a03fb3ab31ba2c24269124/2/5/25076.jpg) Halocarbon 1000N Oil [Poly(chlorotrifluoroethylene), 1,000 centistokes]Catalog Number 25076

Halocarbon 1000N Oil [Poly(chlorotrifluoroethylene), 1,000 centistokes]Catalog Number 25076Inert, non-flammable lubricating oil. Inert, non-flammable lubricating oil. Polymer is a blend of oligomers.

Also used as an ultraviscous solvent for ¹H NMR spectroscopy to better identify individual components in a complex mixture. The ultraviscous polymer solvent (mixed as 80% Halocarbon / 20% CDCl3) greatly reduces the molecular tumbling of small molecules, thereby making the nuclear Overhauser effect (NOE) very large and of negative sign.

-

Poly(tetrafluoroethylene) (Teflon™ 30B) 60 wt % DispersionCatalog Number 21539

Poly(tetrafluoroethylene) (Teflon™ 30B) 60 wt % DispersionCatalog Number 21539This inert, non-ionic Polytetrafluoroethylene (PTFE) dispersion can be used for applications that require excellent chemical and temperature stability. Typical uses include electronic and metallic surface coatings, anti-drip additive for plastics, and binder for battery anode/cathode matrixes. Can be used anywhere a highly inert, stable, non-stick coating is desirable.

-

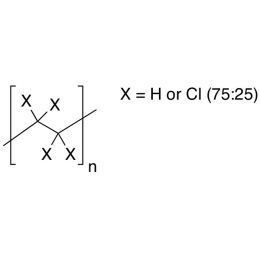

Polyethylene, chlorinated, 25% ClCatalog Number 01814

Polyethylene, chlorinated, 25% ClCatalog Number 01814Useful as primer or coating resin due to good adhesion properties. Randomly chlorinated HDPE.

-

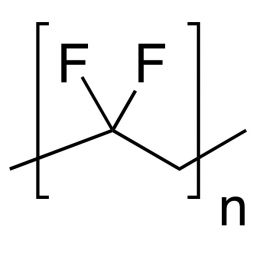

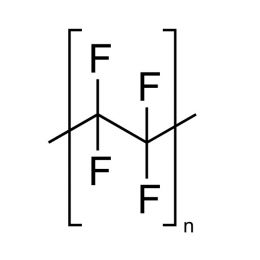

Poly(vinylidene fluoride)Catalog Number 18734

Poly(vinylidene fluoride)Catalog Number 18734Inert coating resin.

Polydispersity 2.5-3.0

-

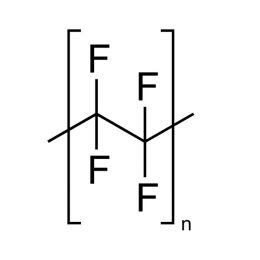

Poly(chlorotrifluroethylene)Catalog Number 15176

Poly(chlorotrifluroethylene)Catalog Number 15176Inert liquid for high temperature baths.

-

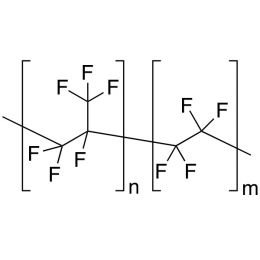

Fluorinated Ethylene Propylene Copolymer (Melt Flow Index 10-35 MI)Catalog Number 24778

Fluorinated Ethylene Propylene Copolymer (Melt Flow Index 10-35 MI)Catalog Number 24778Fluorinated copolymers of ethylene and propylene improve overall performance when formulated into plastics, elastomeric polymers, paints and coatings or inks and lubricants. Exhibits high release characteristics, excellent wear and mar resistance and slip resistance properties when used alone or in blends with other materials. The inherent toughness and high fluorine content imparts improved tear resistance, surface smoothness and flammability resistance in coating and ink formulations.

-

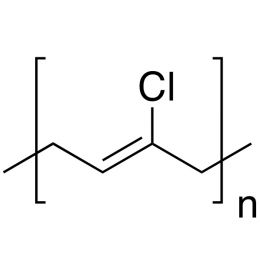

Poly(2-chloro-1,3-butadiene)Catalog Number 21289

Poly(2-chloro-1,3-butadiene)Catalog Number 21289Widely used rubber for applications requiring good solvent resistance.

Neoprene®

-

Poly(tetrafluoroethylene) (Teflon™ 7A)Catalog Number 08816

Poly(tetrafluoroethylene) (Teflon™ 7A)Catalog Number 08816Inert polymer.

Nominal diameter: 35µm

-

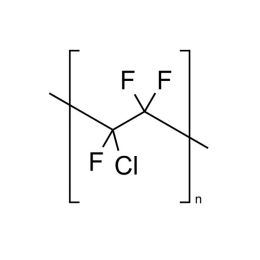

![Halocarbon 200 Oil [Poly(chlorotrifluoroethylene), 200 centistokes] structure](https://www.polysciences.com/media/catalog/product/cache/41caa8e834a03fb3ab31ba2c24269124/2/5/25073.jpg) Halocarbon 200 Oil [Poly(chlorotrifluoroethylene), 200 centistokes]Catalog Number 25073

Halocarbon 200 Oil [Poly(chlorotrifluoroethylene), 200 centistokes]Catalog Number 25073Inert, non-flammable lubricating oil. Polymer is a blend of oligomers. Also used as an inert medium in transgenic studies of fruit fly Drosophilia embryos.

- Pour Point: 10° F (-12° C)

- Cloud Point: 35° F (2° C)

Halogenated Polymers