-

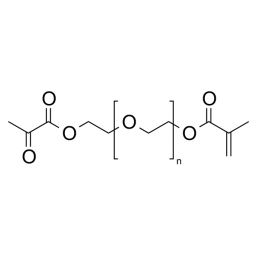

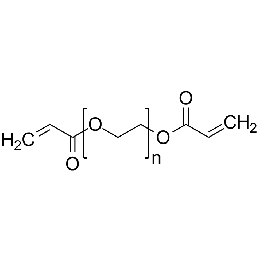

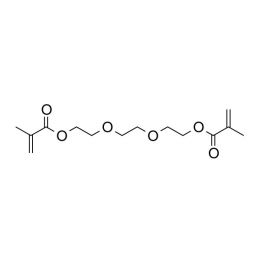

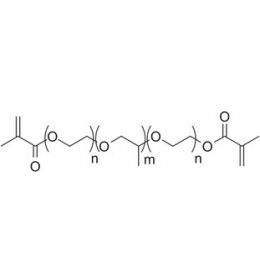

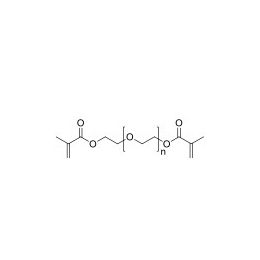

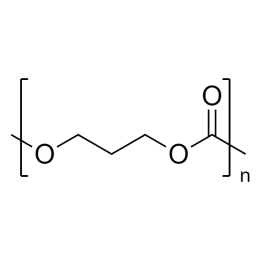

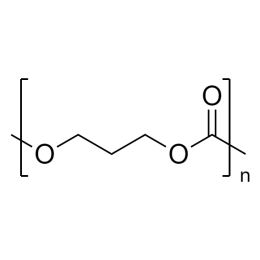

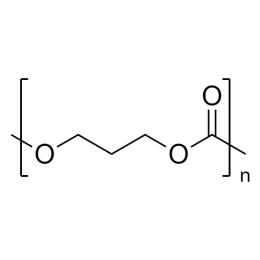

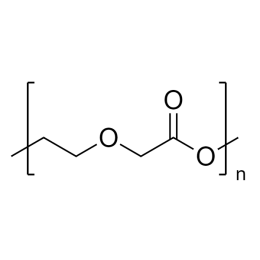

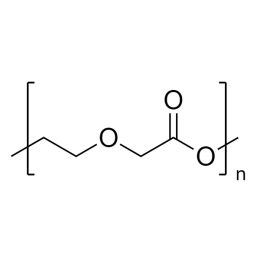

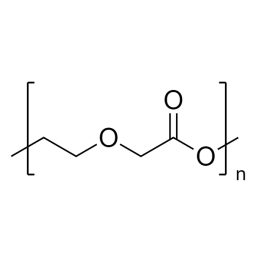

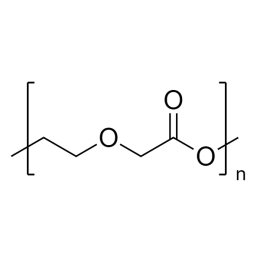

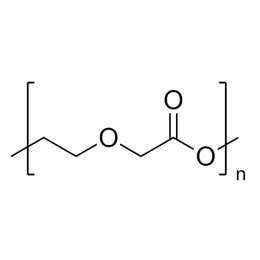

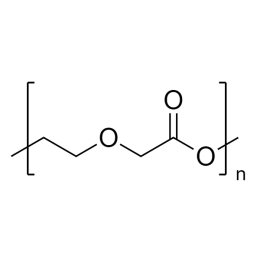

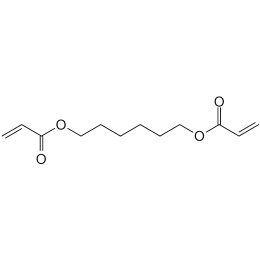

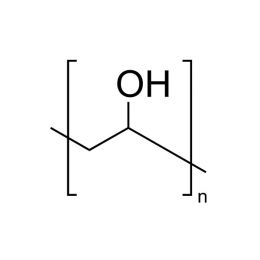

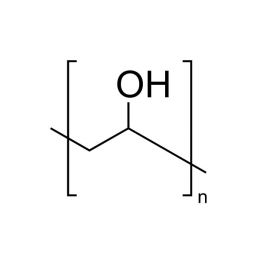

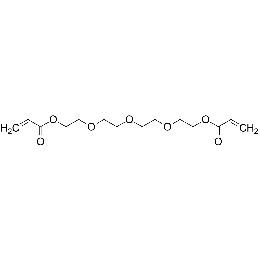

![Poly(ethylene glycol) diacrylate [MW 1,000] | Polysciences, Inc.](https://www.polysciences.com/media/catalog/product/cache/41caa8e834a03fb3ab31ba2c24269124/2/5/25485.png) Polyethylene glycol diacrylate (PEGDA 1000)Catalog Number 25485

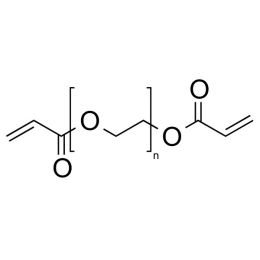

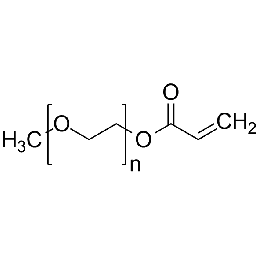

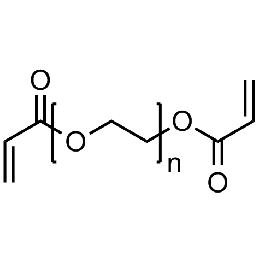

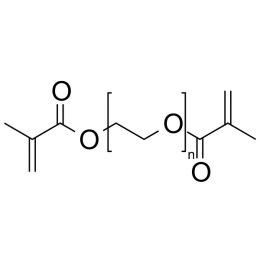

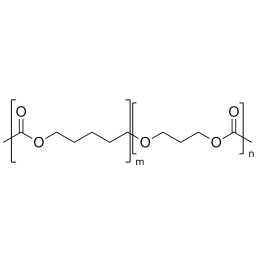

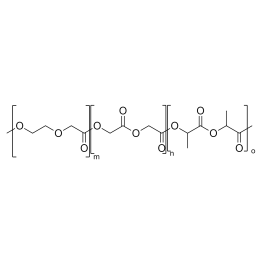

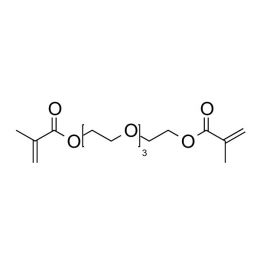

Polyethylene glycol diacrylate (PEGDA 1000)Catalog Number 25485Long-chain, hydrophilic, crosslinking monomer. MW of PEG Block= 1,000

Diacrylate: >95%

-

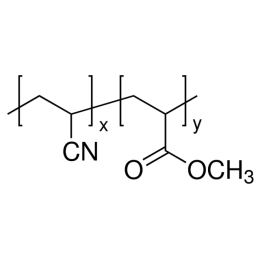

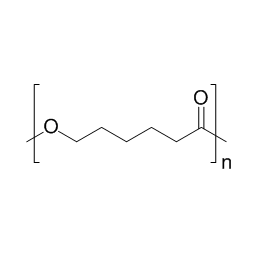

Polyacrylonitrile, co-polymer with 6% methyl acrylate, MW 80,000Catalog Number 25562

Polyacrylonitrile, co-polymer with 6% methyl acrylate, MW 80,000Catalog Number 25562Powder with 40 micron average particle size. Soluble in DMF, DMAc, DMSO.

-

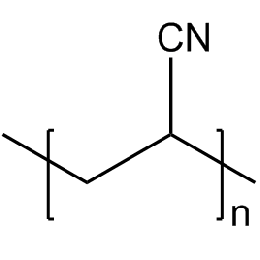

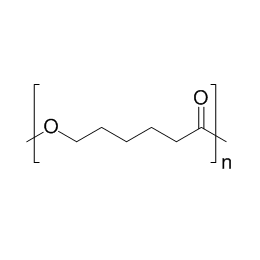

Polyacrylonitrile, MW 200000 (PAN 200000)Catalog Number 25563

Polyacrylonitrile, MW 200000 (PAN 200000)Catalog Number 25563Powder with 40 micron average particle size. Soluble in DMF, DMAc, DMSO.

-

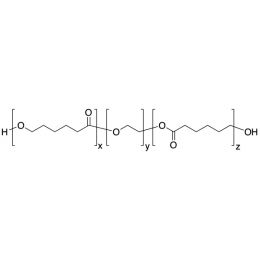

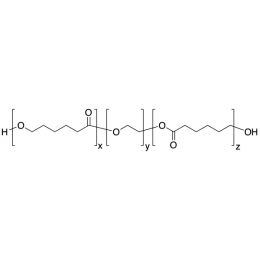

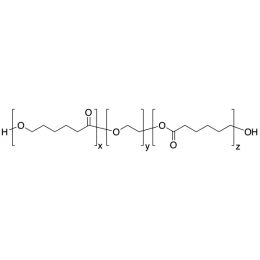

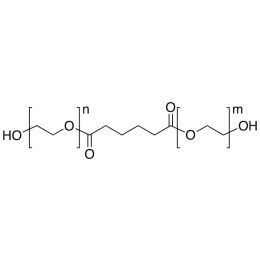

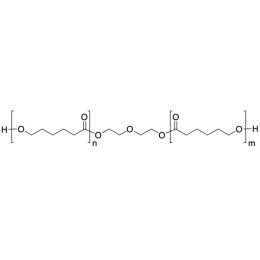

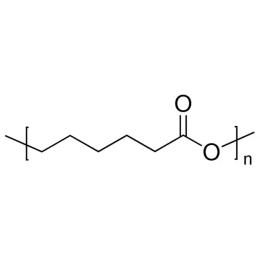

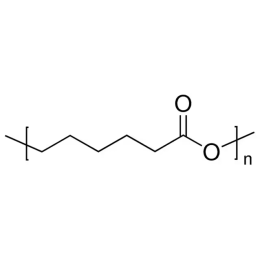

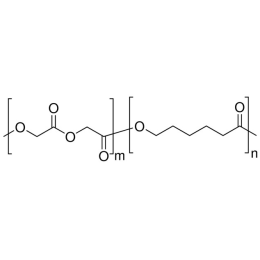

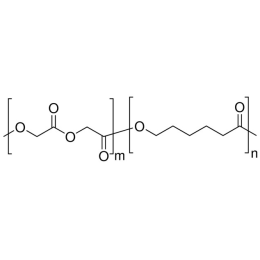

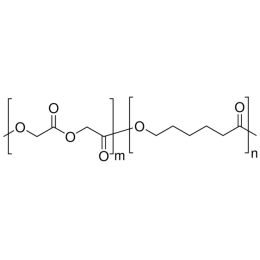

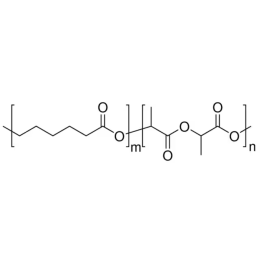

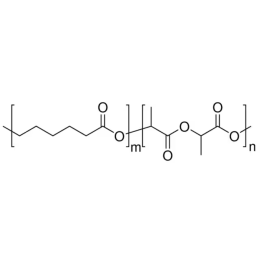

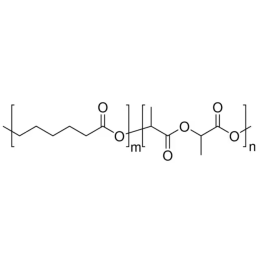

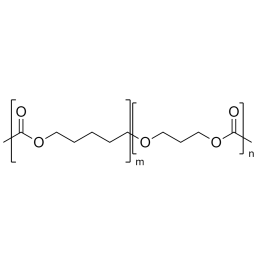

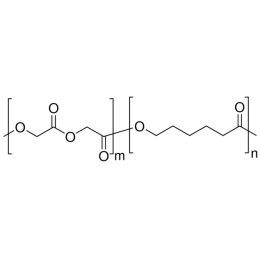

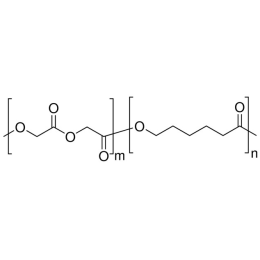

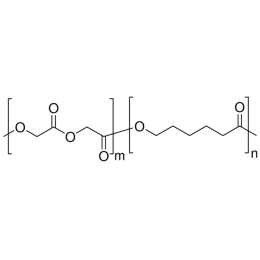

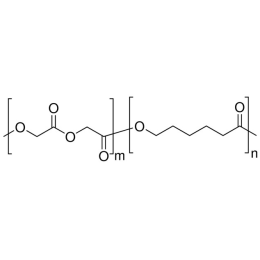

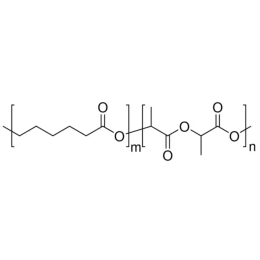

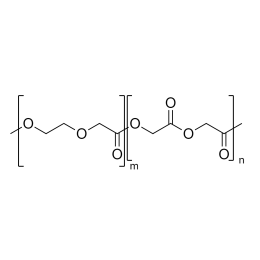

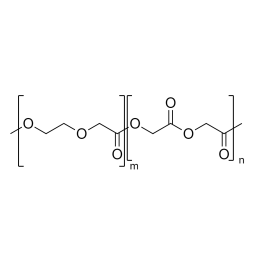

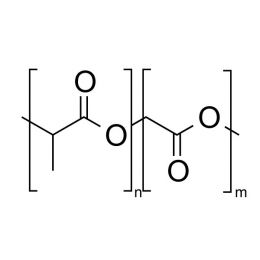

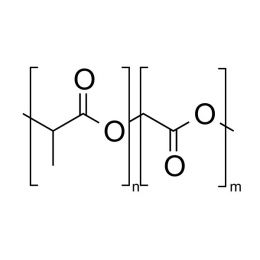

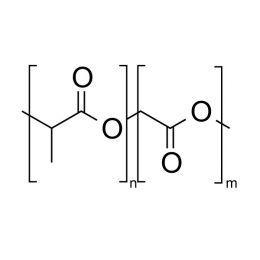

PCL(1,000)-b-PEG(1,000), Diblock PolymerCatalog Number 25010

PCL(1,000)-b-PEG(1,000), Diblock PolymerCatalog Number 25010Caprolactone itself is a biodegradable polyester with a relatively low melting point (60C) but a glass transition temperature (Tg) around -60C. The high crystallinity in the polyester accounts for this property balance. It is made by metal catalyzed ring opening polymerization of epsilon caprolactone. A typical molecular weight of standard polycaprolactone homopolymer is 188k Daltons. By comparison, a 100% polylactic acid homopolymer with Mw 330k Daltons has a (Tg) temperature of +55C and a melting temperature, Tm of about 175C.

-

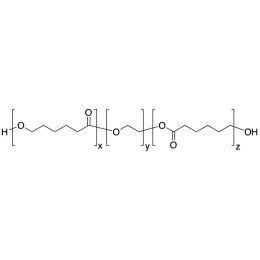

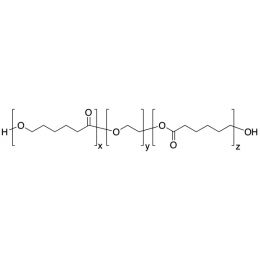

PCL(1,000)-b-PEG(5,000), Diblock PolymerCatalog Number 25012

PCL(1,000)-b-PEG(5,000), Diblock PolymerCatalog Number 25012Caprolactone itself is a biodegradable polyester with a relatively low melting point (60C) but a glass transition temperature (Tg) around -60C. The high crystallinity in the polyester accounts for this property balance. It is made by metal catalyzed ring opening polymerization of epsilon caprolactone. A typical molecular weight of standard polycaprolactone homopolymer is 188k Daltons. By comparison, a 100% polylactic acid homopolymer with Mw 330k Daltons has a (Tg) temperature of +55C and a melting temperature, Tm of about 175C.

-

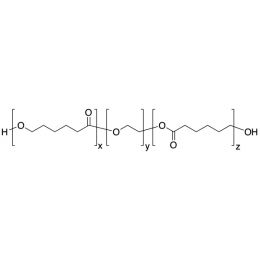

PCL(5,000)-b-PEG(1,000), Diblock PolymerCatalog Number 25022

PCL(5,000)-b-PEG(1,000), Diblock PolymerCatalog Number 25022There is increased interest in biodegradable polymers for both biomedical and industrial applications. Among the leading candidates for biodegradation are caprolactone based materials due to it's approved uses by the FDA for drug delivery systems, sutures, long term implants and adhesion barriers as well as new tissue scaffold host systems.

-

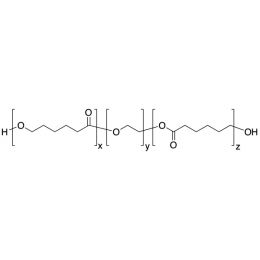

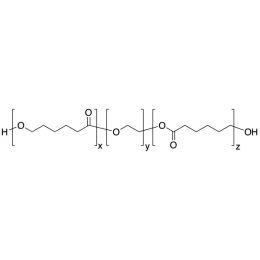

PCL(5,000)-b-PEG(2,000), Diblock PolymerCatalog Number 25023

PCL(5,000)-b-PEG(2,000), Diblock PolymerCatalog Number 25023Caprolactone itself is a biodegradable polyester with a relatively low melting point (60C) but a glass transition temperature (Tg) around -60C. The high crystallinity in the polyester accounts for this property balance. It is made by metal catalyzed ring opening polymerization of epsilon caprolactone. A typical molecular weight of standard polycaprolactone homopolymer is 188k Daltons. By comparison, a 100% polylactic acid homopolymer with Mw 330k Daltons has a (Tg) temperature of +55C and a melting temperature, Tm of about 175C.

-

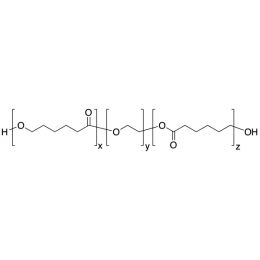

PCL(5,000)-b-PEG(5,000), Diblock PolymerCatalog Number 25024

PCL(5,000)-b-PEG(5,000), Diblock PolymerCatalog Number 25024Caprolactone itself is a biodegradable polyester with a relatively low melting point (60C) but a glass transition temperature (Tg) around -60C. The high crystallinity in the polyester accounts for this property balance. It is made by metal catalyzed ring opening polymerization of epsilon caprolactone. A typical molecular weight of standard polycaprolactone homopolymer is 188k Daltons. By comparison, a 100% polylactic acid homopolymer with Mw 330k Daltons has a (Tg) temperature of +55C and a melting temperature, Tm of about 175C.

-

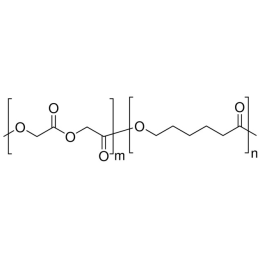

PCL(1,000)-b-PEG(10,000)-b-PCL(1,000), Triblock PolymerCatalog Number 25013

PCL(1,000)-b-PEG(10,000)-b-PCL(1,000), Triblock PolymerCatalog Number 25013Caprolactone itself is a biodegradable polyester with a relatively low melting point (60C) but a glass transition temperature (Tg) around -60C. The high crystallinity in the polyester accounts for this property balance. It is made by metal catalyzed ring opening polymerization of epsilon caprolactone. A typical molecular weight of standard polycaprolactone homopolymer is 188k Daltons. By comparison, a 100% polylactic acid homopolymer with Mw 330k Daltons has a (Tg) temperature of +55C and a melting temperature, Tm of about 175C.

-

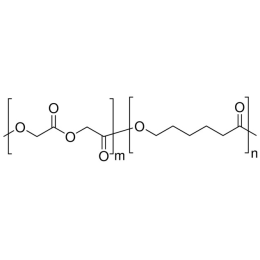

PCL(5,000)-b-PEG(1,000)-b-PCL(5,000), Triblock PolymerCatalog Number 25014

PCL(5,000)-b-PEG(1,000)-b-PCL(5,000), Triblock PolymerCatalog Number 25014Caprolactone itself is a biodegradable polyester with a relatively low melting point (60C) but a glass transition temperature (Tg) around -60C. The high crystallinity in the polyester accounts for this property balance. It is made by metal catalyzed ring opening polymerization of epsilon caprolactone. A typical molecular weight of standard polycaprolactone homopolymer is 188k Daltons. By comparison, a 100% polylactic acid homopolymer with Mw 330k Daltons has a (Tg) temperature of +55C and a melting temperature, Tm of about 175C.

-

PCL(5,000)-b-PEG(2,000)-b-PCL(5,000), Triblock PolymerCatalog Number 25015

PCL(5,000)-b-PEG(2,000)-b-PCL(5,000), Triblock PolymerCatalog Number 25015Caprolactone itself is a biodegradable polyester with a relatively low melting point (60C) but a glass transition temperature (Tg) around -60C. The high crystallinity in the polyester accounts for this property balance. It is made by metal catalyzed ring opening polymerization of epsilon caprolactone. A typical molecular weight of standard polycaprolactone homopolymer is 188k Daltons. By comparison, a 100% polylactic acid homopolymer with Mw 330k Daltons has a (Tg) temperature of +55C and a melting temperature, Tm of about 175C.

-

PCL(5,000)-b-PEG(5,000)-b-PCL(5,000), Triblock PolymerCatalog Number 25016

PCL(5,000)-b-PEG(5,000)-b-PCL(5,000), Triblock PolymerCatalog Number 25016Caprolactone itself is a biodegradable polyester with a relatively low melting point (60C) but a glass transition temperature (Tg) around -60C. The high crystallinity in the polyester accounts for this property balance. It is made by metal catalyzed ring opening polymerization of epsilon caprolactone. A typical molecular weight of standard polycaprolactone homopolymer is 188k Daltons. By comparison, a 100% polylactic acid homopolymer with Mw 330k Daltons has a (Tg) temperature of +55C and a melting temperature, Tm of about 175C.

-

PCL(1,000)-b-PEG(1,000)-b-PCL(1,000), Triblock PolymerCatalog Number 25019

PCL(1,000)-b-PEG(1,000)-b-PCL(1,000), Triblock PolymerCatalog Number 25019Caprolactone itself is a biodegradable polyester with a relatively low melting point (60C) but a glass transition temperature (Tg) around -60C. The high crystallinity in the polyester accounts for this property balance. It is made by metal catalyzed ring opening polymerization of epsilon caprolactone. A typical molecular weight of standard polycaprolactone homopolymer is 188k Daltons. By comparison, a 100% polylactic acid homopolymer with Mw 330k Daltons has a (Tg) temperature of +55C and a melting temperature, Tm of about 175C.

-

PCL(1,000)-b-PEG(2,000)-b-PCL(1,000), Triblock PolymerCatalog Number 25020

PCL(1,000)-b-PEG(2,000)-b-PCL(1,000), Triblock PolymerCatalog Number 25020Caprolactone itself is a biodegradable polyester with a relatively low melting point (60C) but a glass transition temperature (Tg) around -60C. The high crystallinity in the polyester accounts for this property balance. It is made by metal catalyzed ring opening polymerization of epsilon caprolactone. A typical molecular weight of standard polycaprolactone homopolymer is 188k Daltons. By comparison, a 100% polylactic acid homopolymer with Mw 330k Daltons has a (Tg) temperature of +55C and a melting temperature, Tm of about 175C.

-

PCL(1,000)-b-PEG(6,000)-b-PCL(1,000), Triblock PolymerCatalog Number 25021

PCL(1,000)-b-PEG(6,000)-b-PCL(1,000), Triblock PolymerCatalog Number 25021Caprolactone itself is a biodegradable polyester with a relatively low melting point (60C) but a glass transition temperature (Tg) around -60C. The high crystallinity in the polyester accounts for this property balance. It is made by metal catalyzed ring opening polymerization of epsilon caprolactone. A typical molecular weight of standard polycaprolactone homopolymer is 188k Daltons. By comparison, a 100% polylactic acid homopolymer with Mw 330k Daltons has a (Tg) temperature of +55C and a melting temperature, Tm of about 175C.

-

PCL(5,000)-b-PEG(10,000)-b-PCL(5,000), Triblock PolymerCatalog Number 25025

PCL(5,000)-b-PEG(10,000)-b-PCL(5,000), Triblock PolymerCatalog Number 25025Caprolactone itself is a biodegradable polyester with a relatively low melting point (60C) but a glass transition temperature (Tg) around -60C. The high crystallinity in the polyester accounts for this property balance. It is made by metal catalyzed ring opening polymerization of epsilon caprolactone. A typical molecular weight of standard polycaprolactone homopolymer is 188k Daltons. By comparison, a 100% polylactic acid homopolymer with Mw 330k Daltons has a (Tg) temperature of +55C and a melting temperature, Tm of about 175C.

-

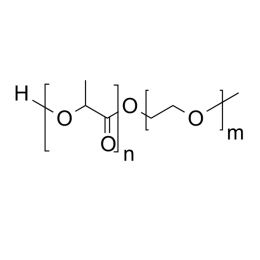

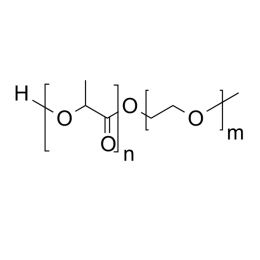

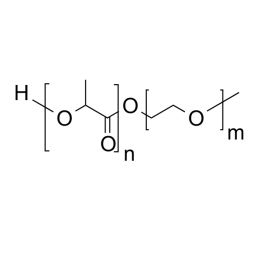

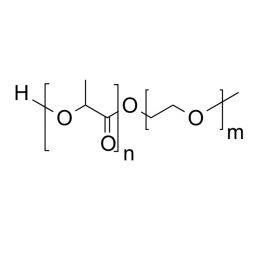

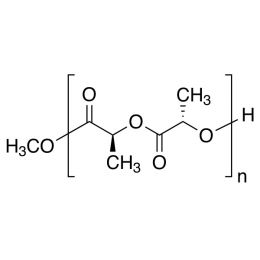

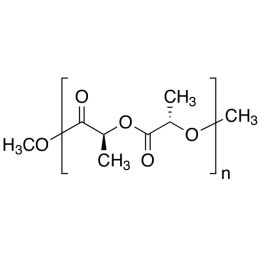

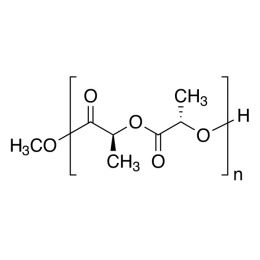

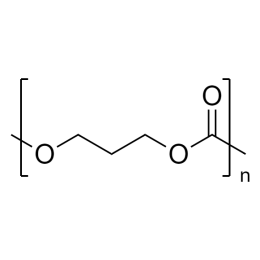

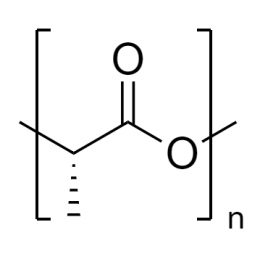

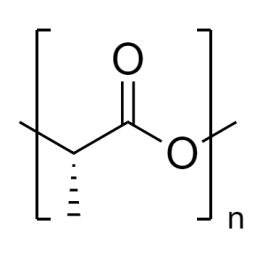

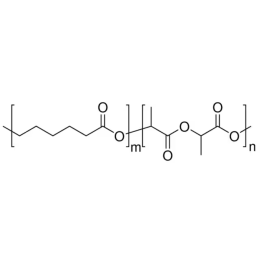

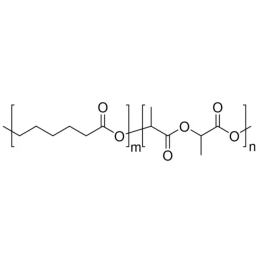

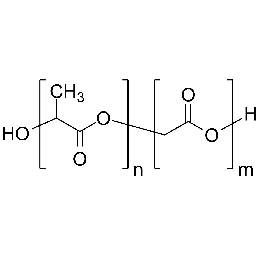

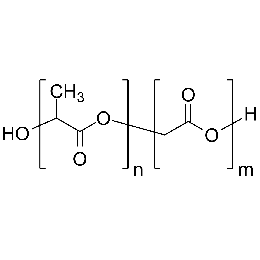

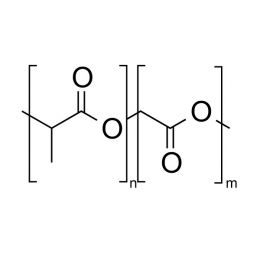

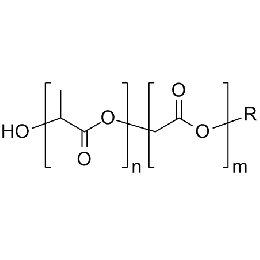

PEG(350)-b-PLA(300), Diblock PolymerCatalog Number 24375

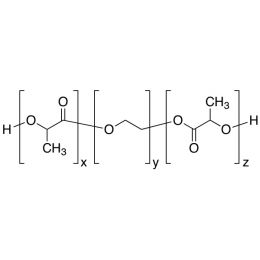

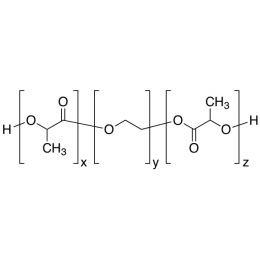

PEG(350)-b-PLA(300), Diblock PolymerCatalog Number 24375Polymer structures featuring polyethylene glycol (PEG), with biodegradable or biocompatabile segments offering micelluar, nano and microsphere morphologies which are useful for controlled release formulations. Molecular weights of blocks controlled by GPC. Alternative structures can be synthesized.

-

PEG(1000)-b-PLA(750), Diblock PolymerCatalog Number 24378

PEG(1000)-b-PLA(750), Diblock PolymerCatalog Number 24378Polymer structures featuring polyethylene glycol (PEG), with biodegradable or biocompatabile segments offering micelluar, nano and microsphere morphologies which are useful for controlled release formulations. Molecular weights of blocks controlled by GPC. Alternative structures can be synthesized.

-

PEG(1000)-b-PLA(5000), Diblock PolymerCatalog Number 24381

PEG(1000)-b-PLA(5000), Diblock PolymerCatalog Number 24381Polymer structures featuring polyethylene glycol (PEG), with biodegradable or biocompatabile segments offering micelluar, nano and microsphere morphologies which are useful for controlled release formulations. Molecular weights of blocks controlled by GPC. Alternative structures can be synthesized.

-

PEG(5000)-b-PLA(1000), Diblock PolymerCatalog Number 24386

PEG(5000)-b-PLA(1000), Diblock PolymerCatalog Number 24386Polymer structures featuring polyethylene glycol (PEG), with biodegradable or biocompatabile segments offering micelluar, nano and microsphere morphologies which are useful for controlled release formulations. Molecular weights of blocks controlled by GPC. Alternative structures can be synthesized.

-

PEG(5000)-b-PLA(5000), Diblock PolymerCatalog Number 24389

PEG(5000)-b-PLA(5000), Diblock PolymerCatalog Number 24389Polymer structures featuring polyethylene glycol (PEG), with biodegradable or biocompatabile segments offering micelluar, nano and microsphere morphologies which are useful for controlled release formulations. Molecular weights of blocks controlled by GPC. Alternative structures can be synthesized.

-

PEG(10,000)-b-PLA(5,000), Diblock PolymerCatalog Number 25017

PEG(10,000)-b-PLA(5,000), Diblock PolymerCatalog Number 25017Polymer structures featuring polyethylene glycol (PEG), with biodegradable or biocompatabile segments offering micelluar, nano and microsphere morphologies which are useful for controlled release formulations. Molecular weights of blocks controlled by GPC. Alternative structures can be synthesized.

-

PEG(5000)-b-PLA(10,000), Diblock PolymerCatalog Number 25018

PEG(5000)-b-PLA(10,000), Diblock PolymerCatalog Number 25018Polymer structures featuring polyethylene glycol (PEG), with biodegradable or biocompatabile segments offering micelluar, nano and microsphere morphologies which are useful for controlled release formulations. Molecular weights of blocks controlled by GPC. Alternative structures can be synthesized.

-

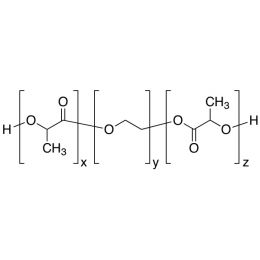

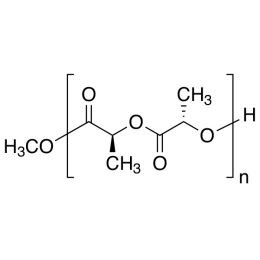

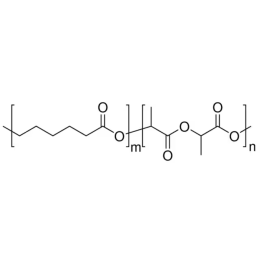

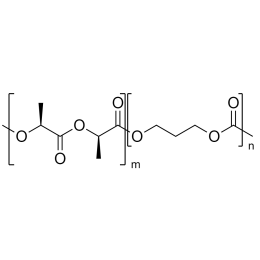

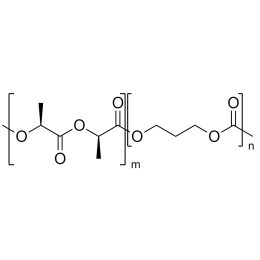

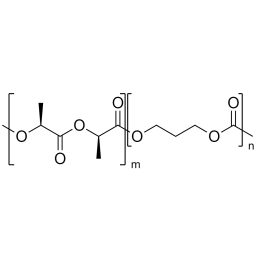

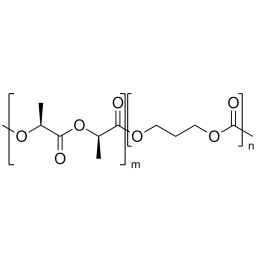

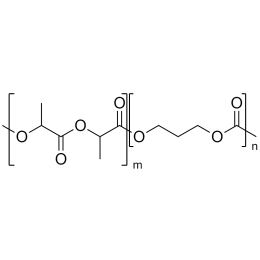

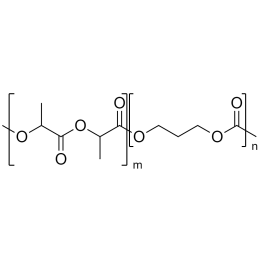

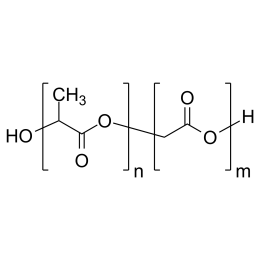

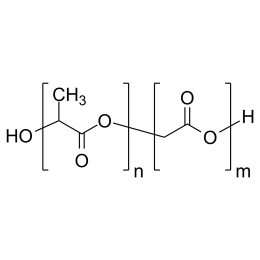

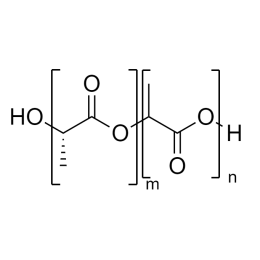

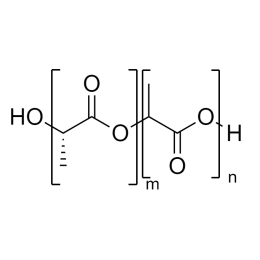

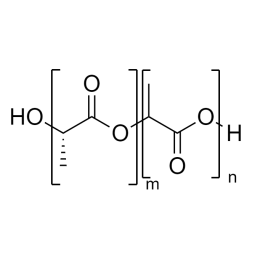

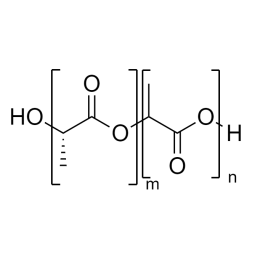

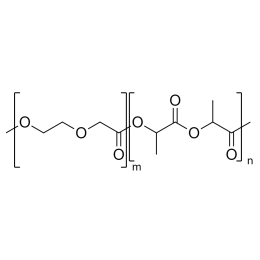

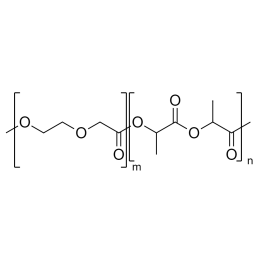

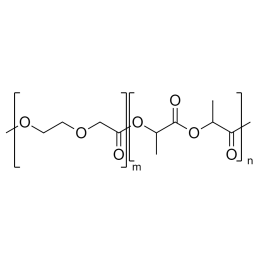

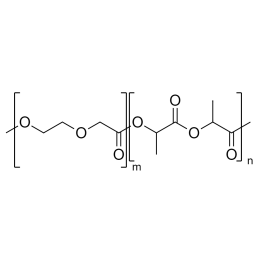

PLA(1000)-b-PEG(1000)-b-PLA(1000), Triblock PolymerCatalog Number 24500

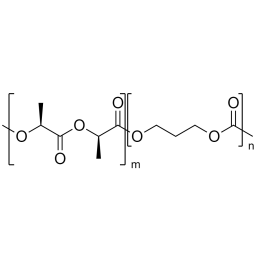

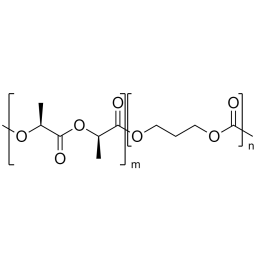

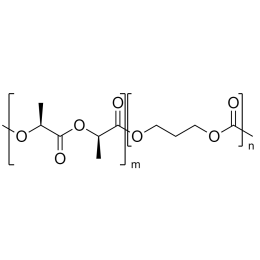

PLA(1000)-b-PEG(1000)-b-PLA(1000), Triblock PolymerCatalog Number 24500Polymer structures featuring polyethylene glycol (PEG), with biodegradable or biocompatabile segments offering micelluar, nano and microsphere morphologies which are useful for controlled release formulations. Molecular weights of blocks controlled by GPC. Alternative structures can be synthesized.

-

PLA(2000)-b-PEG(1000)-b-PLA(2000), Triblock PolymerCatalog Number 24501

PLA(2000)-b-PEG(1000)-b-PLA(2000), Triblock PolymerCatalog Number 24501Polymer structures featuring polyethylene glycol (PEG), with biodegradable or biocompatabile segments offering micelluar, nano and microsphere morphologies which are useful for controlled release formulations. Molecular weights of blocks controlled by GPC. Alternative structures can be synthesized.

-

PLA(5000)-b-PEG(1000)-b-PLA(5000), Triblock PolymerCatalog Number 24502

PLA(5000)-b-PEG(1000)-b-PLA(5000), Triblock PolymerCatalog Number 24502Polymer structures featuring polyethylene glycol (PEG), with biodegradable or biocompatabile segments offering micelluar, nano and microsphere morphologies which are useful for controlled release formulations. Molecular weights of blocks controlled by GPC. Alternative structures can be synthesized.

-

PLA(1000)-b-PEG(4000)-b-PLA(1000), Triblock PolymerCatalog Number 24503

PLA(1000)-b-PEG(4000)-b-PLA(1000), Triblock PolymerCatalog Number 24503Polymer structures featuring polyethylene glycol (PEG), with biodegradable or biocompatabile segments offering micelluar, nano and microsphere morphologies which are useful for controlled release formulations. Molecular weights of blocks controlled by GPC. Alternative structures can be synthesized.

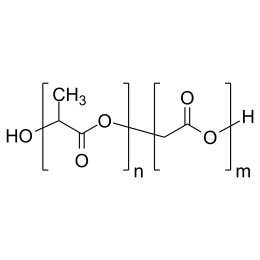

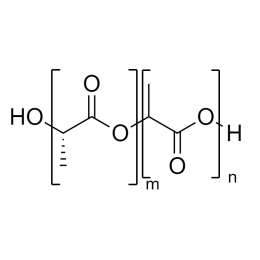

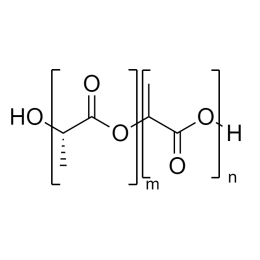

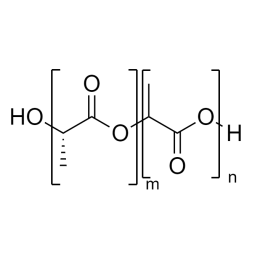

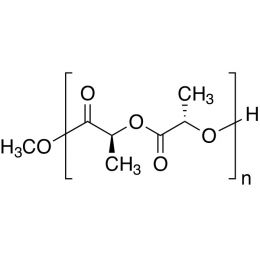

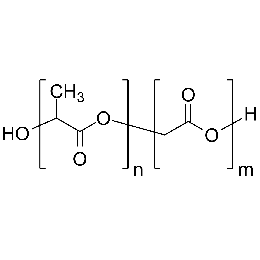

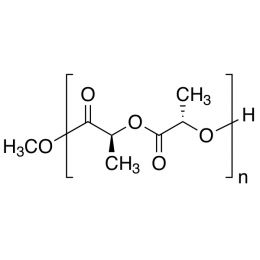

A new class of polymeric biomaterials is emerging. The biodegradability of polymers based on lactic acid(LA) and its copolymers with ethylene glycol (EG) opens up new avenues for drug delivery, gene therapy, tissue engineering and determination of cellular pathway mechanisms.

-

PLA(1000)-b-PEG(10,000)-b-PLA(1000), Triblock PolymerCatalog Number 24509

PLA(1000)-b-PEG(10,000)-b-PLA(1000), Triblock PolymerCatalog Number 24509Polymer structures featuring polyethylene glycol (PEG), with biodegradable or biocompatabile segments offering micelluar, nano and microsphere morphologies which are useful for controlled release formulations. Molecular weights of blocks controlled by GPC. Alternative structures can be synthesized.

A new class of polymeric biomaterials is emerging. The biodegradability of polymers based on lactic acid(LA) and its copolymers with ethylene glycol (EG) opens up new avenues for drug delivery, gene therapy, tissue engineering and determination of cellular pathway mechanisms.

-

PLA(5,000)-b-PEG(10,000)-b-PLA(5,000), Triblock PolymerCatalog Number 25026

PLA(5,000)-b-PEG(10,000)-b-PLA(5,000), Triblock PolymerCatalog Number 25026Polymer structures featuring polyethylene glycol (PEG), with biodegradable or biocompatabile segments offering micelluar, nano and microsphere morphologies which are useful for controlled release formulations. Molecular weights of blocks controlled by GPC. Alternative structures can be synthesized.

A new class of polymeric biomaterials is emerging. The biodegradability of polymers based on lactic acid(LA) and its copolymers with ethylene glycol (EG) opens up new avenues for drug delivery, gene therapy, tissue engineering and determination of cellular pathway mechanisms.

-

PLA(10,000)-b-PEG(10,000)-b-PLA(10,000), Triblock PolymerCatalog Number 25027

PLA(10,000)-b-PEG(10,000)-b-PLA(10,000), Triblock PolymerCatalog Number 25027Polymer structures featuring polyethylene glycol (PEG), with biodegradable or biocompatabile segments offering micelluar, nano and microsphere morphologies which are useful for controlled release formulations. Molecular weights of blocks controlled by GPC. Alternative structures can be synthesized.

-

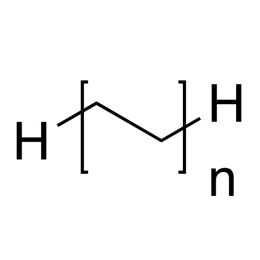

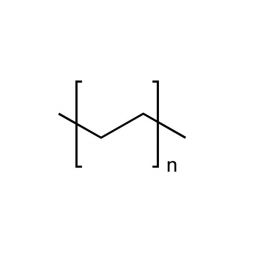

Polyethylene, Chromatographic GradeCatalog Number 15184

Polyethylene, Chromatographic GradeCatalog Number 15184Hydrophobic, easily processed or fabricated, resin.

Soluble in: xylene, tetralin, TCE @ 50-60°

20μ powder chromatographic (reverse phase HPLC) grade

-

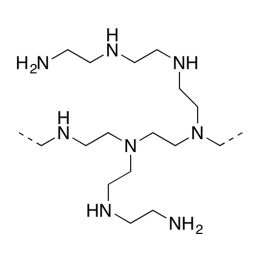

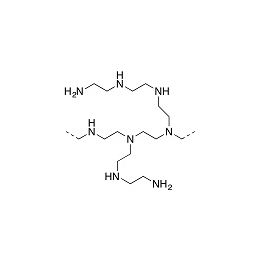

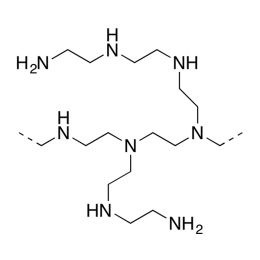

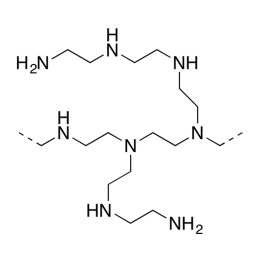

Polyethylenimine, Branched, Mw 70,000, 30% w/v aq. soln. (bPEI 70000 30% soln.)Catalog Number 00618Inquire for availability.Phone: 1(800)523-2575Email: [email protected]

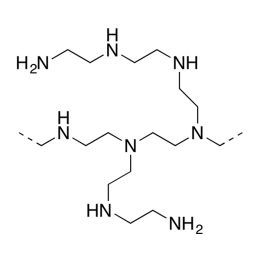

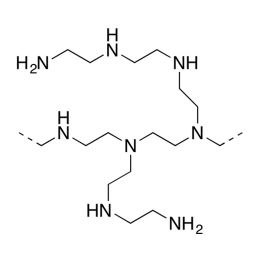

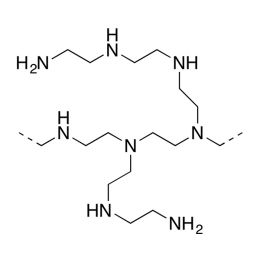

Polyethylenimine, Branched, Mw 70,000, 30% w/v aq. soln. (bPEI 70000 30% soln.)Catalog Number 00618Inquire for availability.Phone: 1(800)523-2575Email: [email protected]Highly branched polyamine with high charge density. Liquid polymers. Polymers contain primary, secondary, and tertiary amine groups in approximately 25/50/25 ratio. 30% soln. in water.

Polydispersity: 17±5.2

-

Polyethylenimine, Branched, Mw 1,200 (bPEI 1200)Catalog Number 06088Branched Polyethylenimine, Mw 1,200 (bPEI 1200) is highly branched liquid water soluble polyamine with high cationic charge density. bPEI 1200 contains primary, secondary, and tertiary amine groups in approximately 25/50/25 ratio.

Polyethylenimine, Branched, Mw 1,200 (bPEI 1200)Catalog Number 06088Branched Polyethylenimine, Mw 1,200 (bPEI 1200) is highly branched liquid water soluble polyamine with high cationic charge density. bPEI 1200 contains primary, secondary, and tertiary amine groups in approximately 25/50/25 ratio. -

Polyethylenimine, Branched, Mw 2000 (bPEI 2000)Catalog Number 06089Branched Polyethylenimine, Mw 1,800 (bPEI 1800) is highly branched liquid water soluble polyamine with high cationic charge density. bPEI 1800 contains primary, secondary, and tertiary amine groups in approximately 25/50/25 ratio.

Polyethylenimine, Branched, Mw 2000 (bPEI 2000)Catalog Number 06089Branched Polyethylenimine, Mw 1,800 (bPEI 1800) is highly branched liquid water soluble polyamine with high cationic charge density. bPEI 1800 contains primary, secondary, and tertiary amine groups in approximately 25/50/25 ratio. -

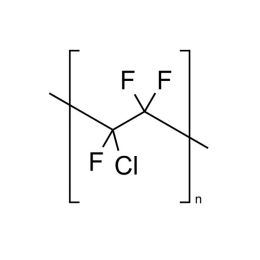

![Halocarbon 400 Oil [Poly(chlorotrifluoroethylene)]](https://www.polysciences.com/media/catalog/product/cache/41caa8e834a03fb3ab31ba2c24269124/2/5/25074.jpg) Halocarbon 400 Oil [Poly(chlorotrifluoroethylene), 400 centistokes]Catalog Number 25074

Halocarbon 400 Oil [Poly(chlorotrifluoroethylene), 400 centistokes]Catalog Number 25074Inert, non-flammable lubricating oil. Polymer is a blend of oligomers. Also used as an inert medium in transgenic studies of fruit fly Drosophilia embryos.

-

![Halocarbon 700 Oil [Poly(chlorotrifluoroethylene)]](https://www.polysciences.com/media/catalog/product/cache/41caa8e834a03fb3ab31ba2c24269124/2/5/25075.jpg) Halocarbon 700 Oil [Poly(chlorotrifluoroethylene), 700 centistokes]Catalog Number 25075

Halocarbon 700 Oil [Poly(chlorotrifluoroethylene), 700 centistokes]Catalog Number 25075Inert, non-flammable lubricating oil. Polymer is a blend of oligomers.

Also used as an inert medium in transgenic studies of fruit fly Drosophilia embryos.

-

![Halocarbon 1000N Oil [Poly(chlorotrifluoroethylene)]](https://www.polysciences.com/media/catalog/product/cache/41caa8e834a03fb3ab31ba2c24269124/2/5/25076.jpg) Halocarbon 1000N Oil [Poly(chlorotrifluoroethylene), 1,000 centistokes]Catalog Number 25076

Halocarbon 1000N Oil [Poly(chlorotrifluoroethylene), 1,000 centistokes]Catalog Number 25076Inert, non-flammable lubricating oil. Inert, non-flammable lubricating oil. Polymer is a blend of oligomers.

Also used as an ultraviscous solvent for ¹H NMR spectroscopy to better identify individual components in a complex mixture. The ultraviscous polymer solvent (mixed as 80% Halocarbon / 20% CDCl3) greatly reduces the molecular tumbling of small molecules, thereby making the nuclear Overhauser effect (NOE) very large and of negative sign.

-

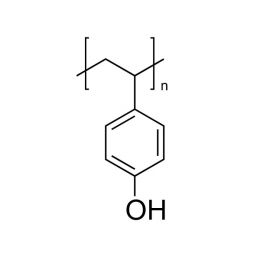

![Poly(4-vinylphenol) [MW 9,000 - 11,000] | Polysciences, Inc.](https://www.polysciences.com/media/catalog/product/cache/41caa8e834a03fb3ab31ba2c24269124/2/5/25447.jpg) Poly(4-vinylphenol) [MW 9,000 - 11,000]Catalog Number 25447

Poly(4-vinylphenol) [MW 9,000 - 11,000]Catalog Number 25447Reactive polyphenol. Has applications in photoresists.

Polydispersity ~3

-

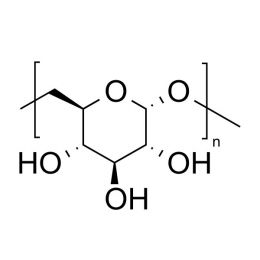

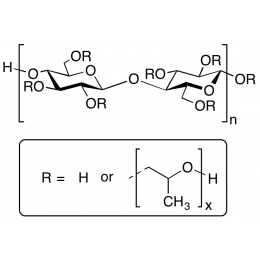

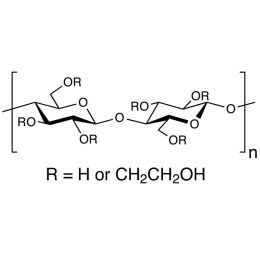

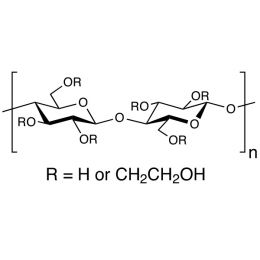

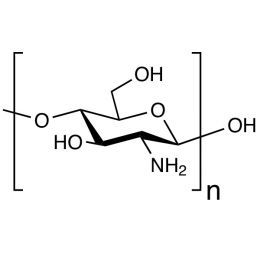

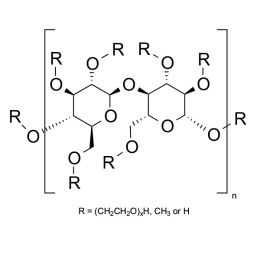

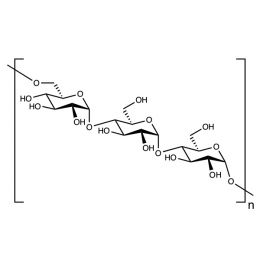

DextranCatalog Number 01341

DextranCatalog Number 01341Water soluble carbohydrate with many pharmaceutical and technical uses.

-

![Dextran [MW 100,000-200,000]](https://www.polysciences.com/media/catalog/product/cache/41caa8e834a03fb3ab31ba2c24269124/0/5/05056.jpg) Dextran [MW 100,000-200,000]Catalog Number 05056

Dextran [MW 100,000-200,000]Catalog Number 05056Water soluble carbohydrate with many pharmaceutical and technical uses.

-

![Dextran [MW 200,000-300,000]](https://www.polysciences.com/media/catalog/product/cache/41caa8e834a03fb3ab31ba2c24269124/2/2/22500.jpg) Dextran [MW 200,000-300,000]Catalog Number 22500

Dextran [MW 200,000-300,000]Catalog Number 22500Water soluble carbohydrate with many pharmaceutical and technical uses.

-

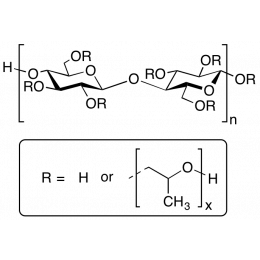

![Hydroxypropyl Cellulose [3-6 cP]](https://www.polysciences.com/media/catalog/product/cache/41caa8e834a03fb3ab31ba2c24269124/2/5/25730_3.png) Hydroxypropyl Cellulose [3-6 cP]Catalog Number 25727

Hydroxypropyl Cellulose [3-6 cP]Catalog Number 25727HPC is a hydrophilic polymer used for drug encapsulants, opthalmic lubricants and transdermal patches. Also used as a general thickener.

-

Hydroxypropyl Cellulose [6-10 cP]Catalog Number 25728

Hydroxypropyl Cellulose [6-10 cP]Catalog Number 25728HPC is a hydrophilic polymer used for drug encapsulants, opthalmic lubricants and transdermal patches. Also used as a general thickener.

-

![Hydroxypropyl Cellulose [150-400 cP]](https://www.polysciences.com/media/catalog/product/cache/41caa8e834a03fb3ab31ba2c24269124/2/5/25730_2.png) Hydroxypropyl Cellulose [150-400 cP]Catalog Number 25729

Hydroxypropyl Cellulose [150-400 cP]Catalog Number 25729HPC is a hydrophilic polymer used for drug encapsulants, opthalmic lubricants and transdermal patches. Also used as a general thickener.

-

Hydroxypropyl Cellulose [1,000-4,000 cP]Catalog Number 25730

Hydroxypropyl Cellulose [1,000-4,000 cP]Catalog Number 25730HPC is a hydrophilic polymer used for drug encapsulants, opthalmic lubricants and transdermal patches. Also used as a general thickener.

-

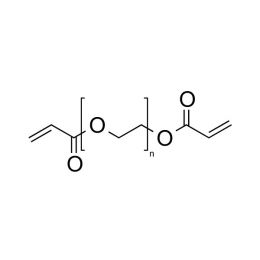

Polyethylene glycol diacrylate (PEGDA 200)Catalog Number 00669

Polyethylene glycol diacrylate (PEGDA 200)Catalog Number 00669Long-chain, hydrophilic, crosslinking monomer. MW PEG Block = 200

-

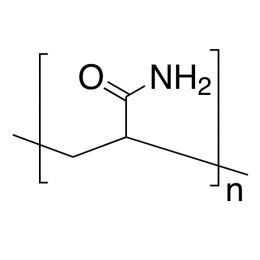

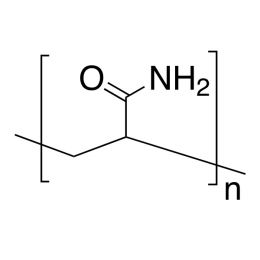

Polyacrylamide, Mw 10,000, 50 wt. % in H2OCatalog Number 22581

Polyacrylamide, Mw 10,000, 50 wt. % in H2OCatalog Number 22581Low molecular weight nonionic water-soluble polymer, used primarily as a flocculant. 50% solution in water. Unit weights are weights of solution.

-

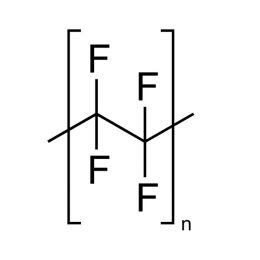

Poly(tetrafluoroethylene) (Teflon™ 30B) 60 wt % DispersionCatalog Number 21539

Poly(tetrafluoroethylene) (Teflon™ 30B) 60 wt % DispersionCatalog Number 21539This inert, non-ionic Polytetrafluoroethylene (PTFE) dispersion can be used for applications that require excellent chemical and temperature stability. Typical uses include electronic and metallic surface coatings, anti-drip additive for plastics, and binder for battery anode/cathode matrixes. Can be used anywhere a highly inert, stable, non-stick coating is desirable.

-

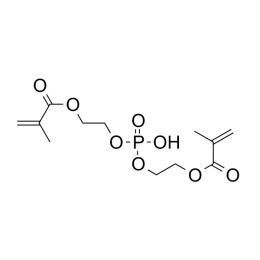

Bis(2-methacryloxyethyl) phosphateCatalog Number 16041

Bis(2-methacryloxyethyl) phosphateCatalog Number 16041Crosslinking monomer. Adhesion promoter through free phosphoric acid group.

-

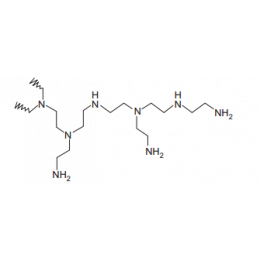

Polyethylenimine, Linear, MW 25000, Transfection Grade (PEI 25K™)Catalog Number 23966Email: [email protected]PEI 25K is a powerful, trusted, and cost-effective transient transfection reagent. In HEK293 and CHO expression systems, PEI offers consistently high gene expression on a wide scale (96 well plates up to 100 L bioreactors). Each year, more researchers and companies turn to Polysciences PEI to gain a critical edge in their work. Relative to most other options, using PEI to prepare transfection reagents in-house can offer as much as a 40% reduction in total transfection costs.

Polyethylenimine, Linear, MW 25000, Transfection Grade (PEI 25K™)Catalog Number 23966Email: [email protected]PEI 25K is a powerful, trusted, and cost-effective transient transfection reagent. In HEK293 and CHO expression systems, PEI offers consistently high gene expression on a wide scale (96 well plates up to 100 L bioreactors). Each year, more researchers and companies turn to Polysciences PEI to gain a critical edge in their work. Relative to most other options, using PEI to prepare transfection reagents in-house can offer as much as a 40% reduction in total transfection costs. -

Cellulose, hydroxyethyl ether (MW 1,000,000)Catalog Number 05568

Cellulose, hydroxyethyl ether (MW 1,000,000)Catalog Number 05568Water-soluble cellulose ether, used as a binder and thickening agent

1,500-2,500 cps (1% soln. in water)

-

Cellulose, hydroxyethyl ether (MW 720,000)Catalog Number 05569Inquire for availability.Phone: 1(800)523-2575Email: [email protected]

Cellulose, hydroxyethyl ether (MW 720,000)Catalog Number 05569Inquire for availability.Phone: 1(800)523-2575Email: [email protected]Water-soluble cellulose ether, used as a binder and thickening agent

Viscosity of 2% AQ = 4,500-6,500 cps

-

Cellulose, hydroxyethyl ether (MW ~90,000)Catalog Number 05570

Cellulose, hydroxyethyl ether (MW ~90,000)Catalog Number 05570Water-soluble cellulose ether, used as a binder and thickening agent

-

Poly(ethylene oxide), MW 100000 (PEO 100K)Catalog Number 06104

Poly(ethylene oxide), MW 100000 (PEO 100K)Catalog Number 06104Water-soluble polymer in a white, free flowing powder. Used to impart viscosity to and modify flow of aqueous solutions. See poly(ethylene glycol) for lower molecular weight analogs. Poly(ethylene glycol) has a broad molecular weight distribution ranging from~ 0.5x to 1.5x the values shown.

Soluble in: acetone, alcohol, chloroform, toluene, dichloromethane

PEO Contains 0.01% BHT, SiO2 1.5% max, alkaline earth oxide as CaO 0.5%,

-

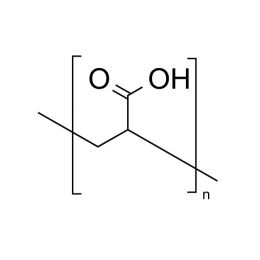

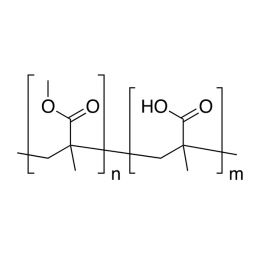

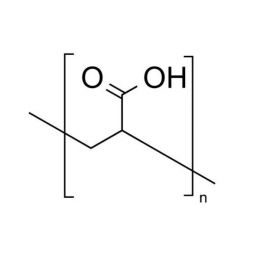

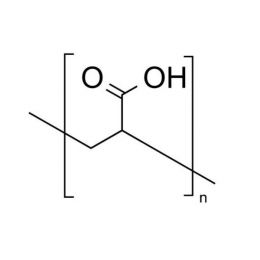

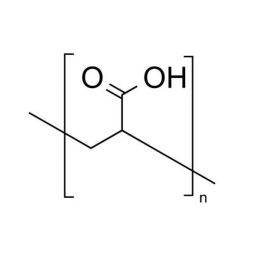

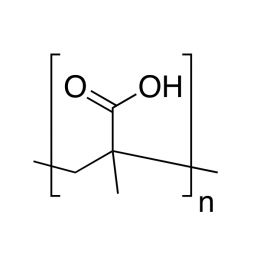

Poly(acrylic acid), 63% soln. in water [MW ~2,000]Catalog Number 06513

Poly(acrylic acid), 63% soln. in water [MW ~2,000]Catalog Number 06513Important anionic water-soluble polymer. Can be crosslinked covalently or ionically to form hydrogels.

Mw/Mn 2.4

63% soln. in water (157.5 g polymer)

-

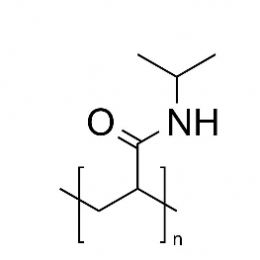

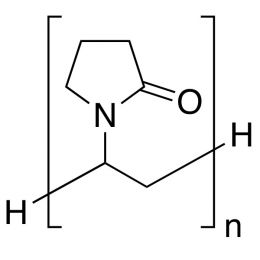

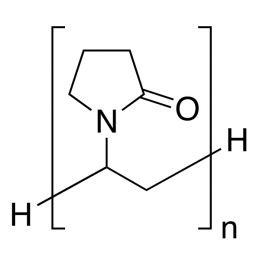

Poly(N-isopropylacrylamide) (PNiPAM)Catalog Number 21458

Poly(N-isopropylacrylamide) (PNiPAM)Catalog Number 21458Polymer is water-soluble at room temperature, insoluble above ~40º. Solubility ceiling has been used in mold and cell growth techniques since cells adhere to polymer film at incubation temperatures and are released as medium is cooled and polymer is dissolved.

-

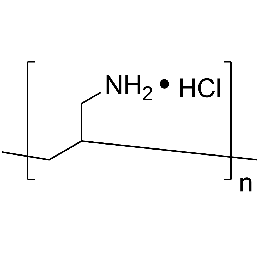

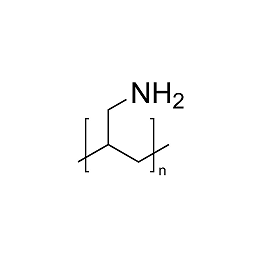

Poly(allylamine hydrochloride), MW 150000, 40% aq. soln.Catalog Number 25673

Poly(allylamine hydrochloride), MW 150000, 40% aq. soln.Catalog Number 25673Polymeric primary amine. 40% AQ solution.

-

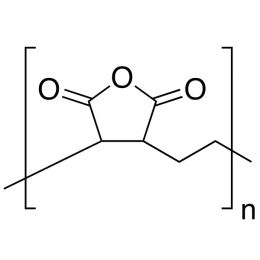

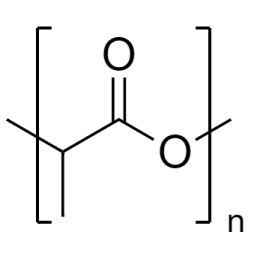

Poly(D,L-lactide), IV 0.2 dl/g, acid-terminatedCatalog Number 26267

Poly(D,L-lactide), IV 0.2 dl/g, acid-terminatedCatalog Number 26267 -

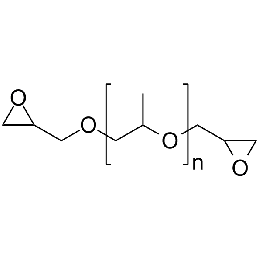

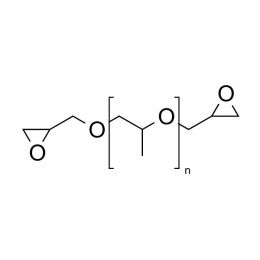

Poly(propylene glycol) (600) diglycidyl etherCatalog Number 24046Inquire for availability.Phone: 1(800)523-2575Email: [email protected]

Poly(propylene glycol) (600) diglycidyl etherCatalog Number 24046Inquire for availability.Phone: 1(800)523-2575Email: [email protected]Crosslinker for amine-, hydroxyl-, and carboxyl-functional polymers.

WPE ~ 530

-

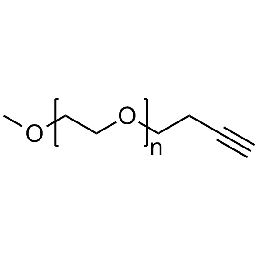

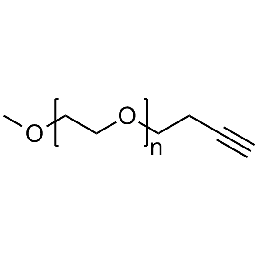

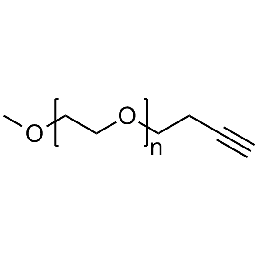

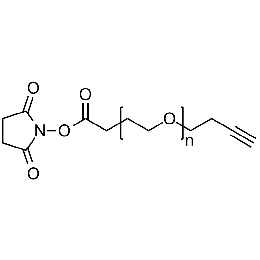

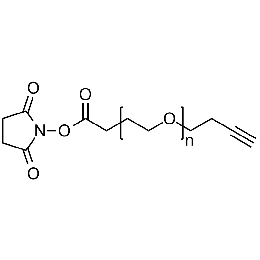

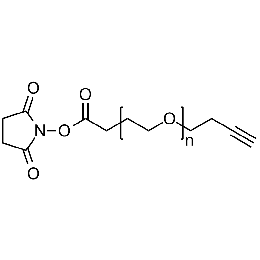

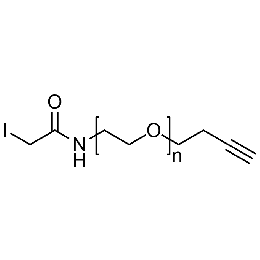

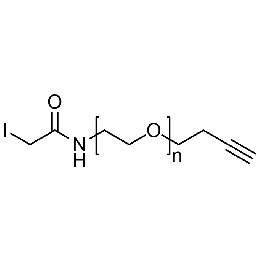

Methoxy PEG alkyne, Mp 750Catalog Number 26019

Methoxy PEG alkyne, Mp 750Catalog Number 26019 -

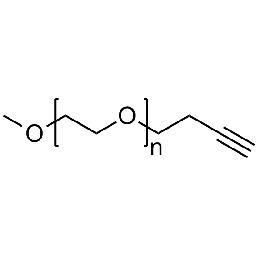

Methoxy PEG alkyne, Mp 2000Catalog Number 26020

Methoxy PEG alkyne, Mp 2000Catalog Number 26020 -

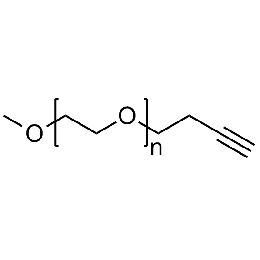

Methoxy PEG alkyne, Mp 5000Catalog Number 26021

Methoxy PEG alkyne, Mp 5000Catalog Number 26021 -

Methoxy PEG alkyne, Mp 10000Catalog Number 26022

Methoxy PEG alkyne, Mp 10000Catalog Number 26022 -

Methoxy PEG alkyne, Mp 20000Catalog Number 26023

Methoxy PEG alkyne, Mp 20000Catalog Number 26023 -

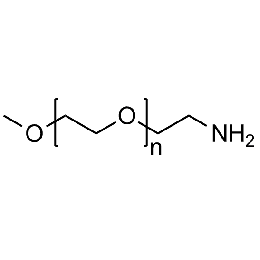

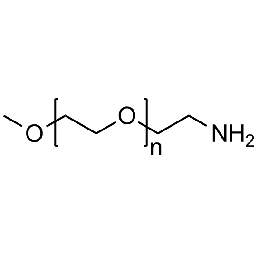

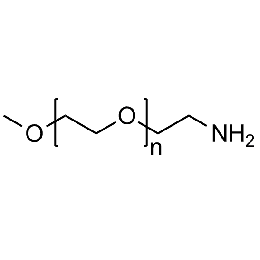

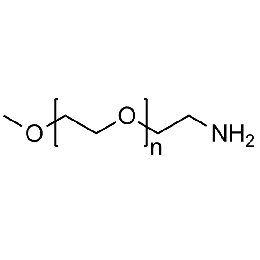

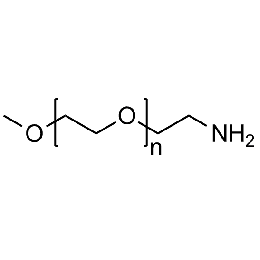

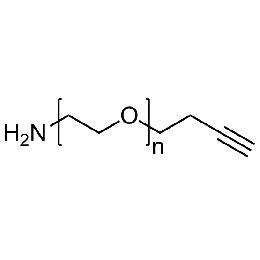

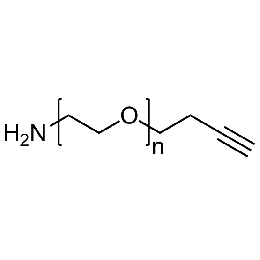

Methoxy PEG amine, Mp 750Catalog Number 26024

Methoxy PEG amine, Mp 750Catalog Number 26024 -

Methoxy PEG amine, Mp 2000Catalog Number 26025

Methoxy PEG amine, Mp 2000Catalog Number 26025 -

Methoxy PEG amine, Mp 5000Catalog Number 26026

Methoxy PEG amine, Mp 5000Catalog Number 26026 -

Methoxy PEG amine, Mp 10000Catalog Number 26027

Methoxy PEG amine, Mp 10000Catalog Number 26027 -

Methoxy PEG amine, Mp 20000Catalog Number 26028

Methoxy PEG amine, Mp 20000Catalog Number 26028 -

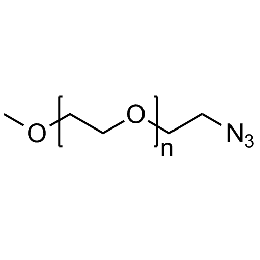

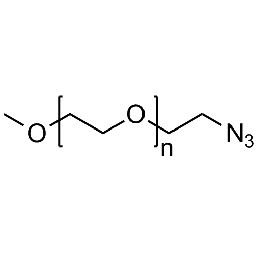

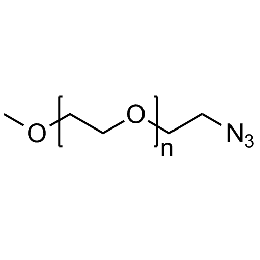

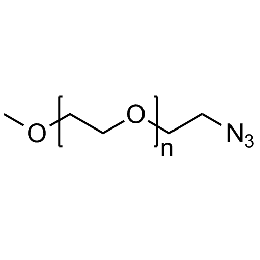

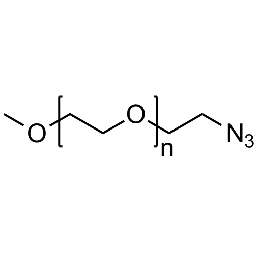

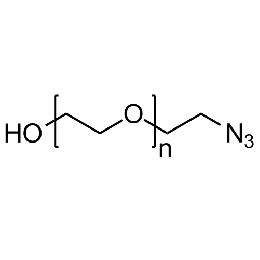

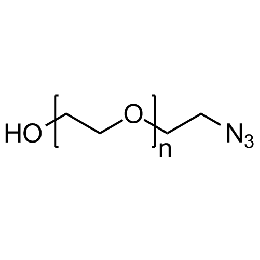

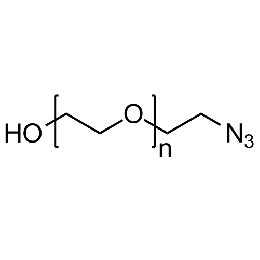

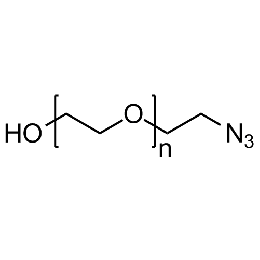

Methoxy PEG azide, Mp 750Catalog Number 26029

Methoxy PEG azide, Mp 750Catalog Number 26029 -

Methoxy PEG azide, Mp 2000Catalog Number 26030

Methoxy PEG azide, Mp 2000Catalog Number 26030 -

Methoxy PEG azide, Mp 5000Catalog Number 26031

Methoxy PEG azide, Mp 5000Catalog Number 26031 -

Methoxy PEG azide, Mp 10000Catalog Number 26032

Methoxy PEG azide, Mp 10000Catalog Number 26032 -

Methoxy PEG azide, Mp 20000Catalog Number 26033

Methoxy PEG azide, Mp 20000Catalog Number 26033 -

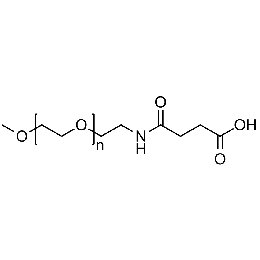

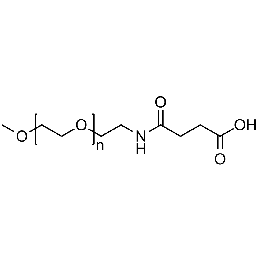

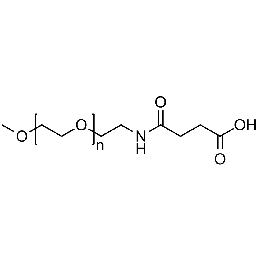

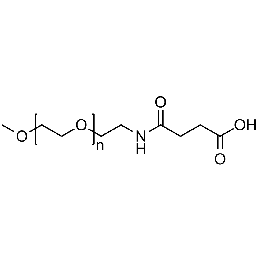

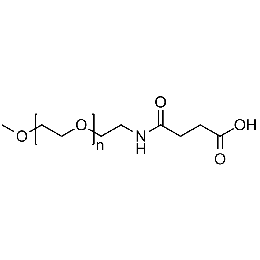

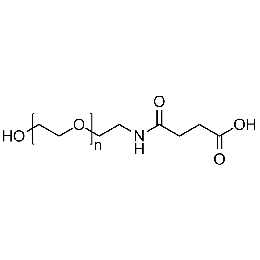

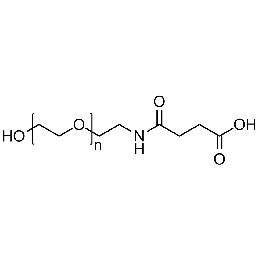

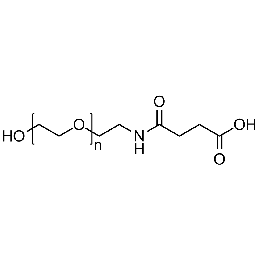

Methoxy PEG carboxylic acid, Mp 750Catalog Number 26034

Methoxy PEG carboxylic acid, Mp 750Catalog Number 26034 -

Methoxy PEG carboxylic acid, Mp 2000Catalog Number 26035

Methoxy PEG carboxylic acid, Mp 2000Catalog Number 26035 -

Methoxy PEG carboxylic acid, Mp 5000Catalog Number 26036

Methoxy PEG carboxylic acid, Mp 5000Catalog Number 26036 -

Methoxy PEG carboxylic acid, Mp 10000Catalog Number 26037

Methoxy PEG carboxylic acid, Mp 10000Catalog Number 26037 -

Methoxy PEG carboxylic acid, Mp 20000Catalog Number 26038

Methoxy PEG carboxylic acid, Mp 20000Catalog Number 26038 -

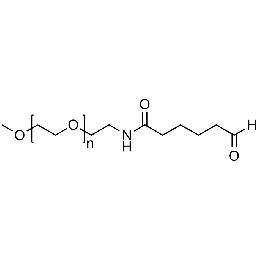

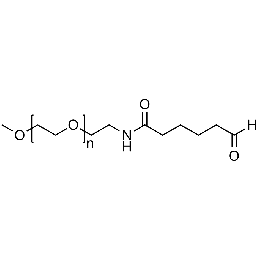

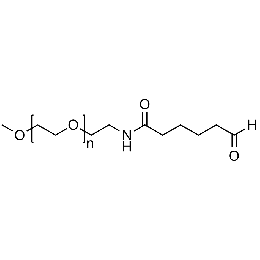

Methoxy PEG aldehyde, Mp 750Catalog Number 26039

Methoxy PEG aldehyde, Mp 750Catalog Number 26039 -

Methoxy PEG aldehyde, Mp 2000Catalog Number 26040

Methoxy PEG aldehyde, Mp 2000Catalog Number 26040 -

Methoxy PEG aldehyde, Mp 5000Catalog Number 26041

Methoxy PEG aldehyde, Mp 5000Catalog Number 26041 -

Methoxy PEG aldehyde, Mp 10000Catalog Number 26042

Methoxy PEG aldehyde, Mp 10000Catalog Number 26042 -

Methoxy PEG aldehyde, Mp 20000Catalog Number 26043

Methoxy PEG aldehyde, Mp 20000Catalog Number 26043 -

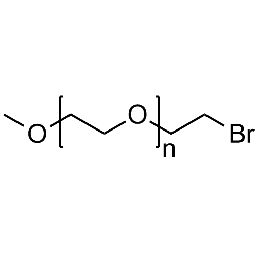

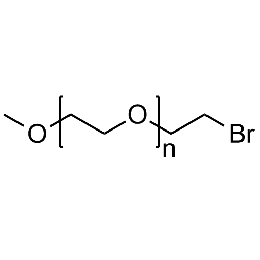

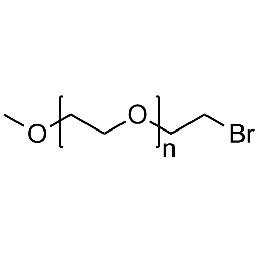

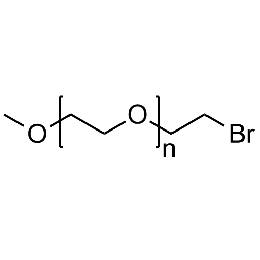

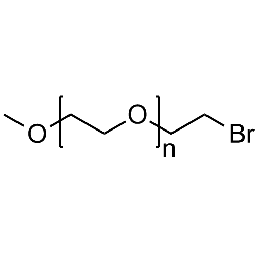

Methoxy PEG bromide, Mp 750Catalog Number 26044

Methoxy PEG bromide, Mp 750Catalog Number 26044 -

Methoxy PEG bromide, Mp 2000Catalog Number 26045

Methoxy PEG bromide, Mp 2000Catalog Number 26045 -

Methoxy PEG bromide, Mp 5000Catalog Number 26046

Methoxy PEG bromide, Mp 5000Catalog Number 26046 -

Methoxy PEG bromide, Mp 10000Catalog Number 26047

Methoxy PEG bromide, Mp 10000Catalog Number 26047 -

Methoxy PEG bromide, Mp 20000Catalog Number 26048

Methoxy PEG bromide, Mp 20000Catalog Number 26048 -

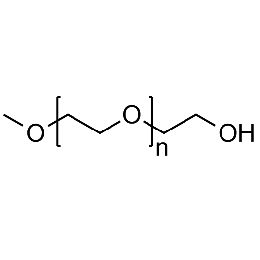

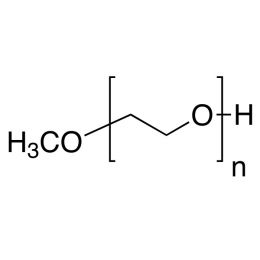

PEG monomethyl ether, Mp 750Catalog Number 26049

PEG monomethyl ether, Mp 750Catalog Number 26049 -

PEG monomethyl ether, Mp 2000Catalog Number 26050

PEG monomethyl ether, Mp 2000Catalog Number 26050 -

PEG monomethyl ether, Mp 5000Catalog Number 26051

PEG monomethyl ether, Mp 5000Catalog Number 26051 -

PEG monomethyl ether, Mp 10000Catalog Number 26052

PEG monomethyl ether, Mp 10000Catalog Number 26052 -

PEG monomethyl ether, Mp 20000Catalog Number 26053

PEG monomethyl ether, Mp 20000Catalog Number 26053 -

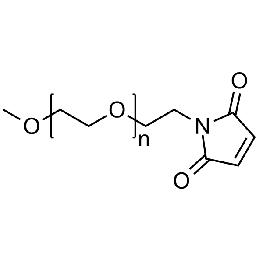

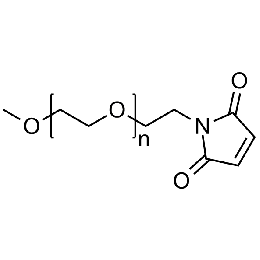

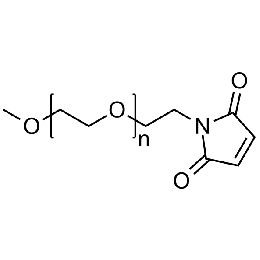

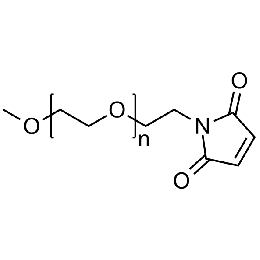

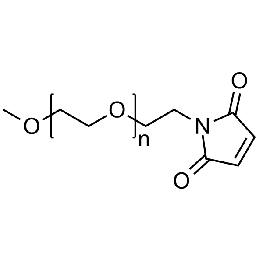

Methoxy PEG maleimide, Mp 750Catalog Number 26054

Methoxy PEG maleimide, Mp 750Catalog Number 26054 -

Methoxy PEG maleimide, Mp 2000Catalog Number 26055

Methoxy PEG maleimide, Mp 2000Catalog Number 26055 -

Methoxy PEG maleimide, Mp 5000Catalog Number 26056

Methoxy PEG maleimide, Mp 5000Catalog Number 26056 -

Methoxy PEG maleimide, Mp 10000Catalog Number 26057

Methoxy PEG maleimide, Mp 10000Catalog Number 26057 -

Methoxy PEG maleimide, Mp 20000Catalog Number 26058

Methoxy PEG maleimide, Mp 20000Catalog Number 26058 -

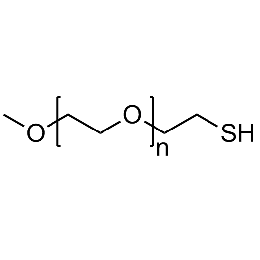

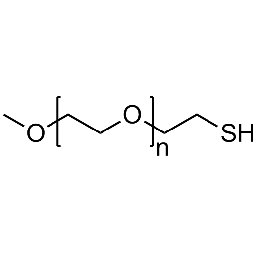

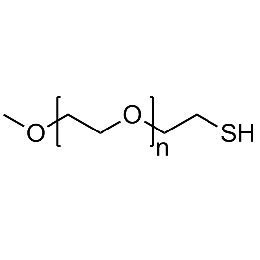

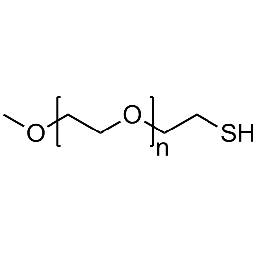

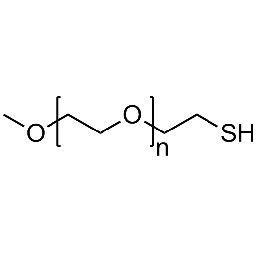

PEG methyl ether thiol, Mp 750Catalog Number 26059

PEG methyl ether thiol, Mp 750Catalog Number 26059 -

PEG methyl ether thiol, Mp 2000Catalog Number 26060

PEG methyl ether thiol, Mp 2000Catalog Number 26060 -

PEG methyl ether thiol, Mp 5000Catalog Number 26061

PEG methyl ether thiol, Mp 5000Catalog Number 26061 -

PEG methyl ether thiol, Mp 10000Catalog Number 26062

PEG methyl ether thiol, Mp 10000Catalog Number 26062 -

PEG methyl ether thiol, Mp 20000Catalog Number 26063

PEG methyl ether thiol, Mp 20000Catalog Number 26063 -

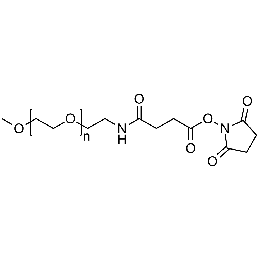

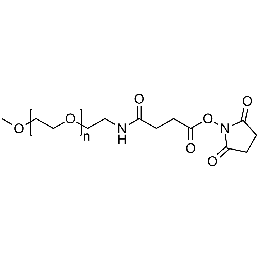

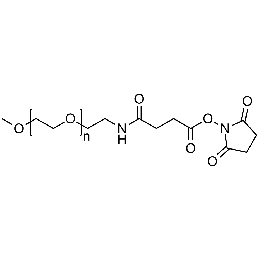

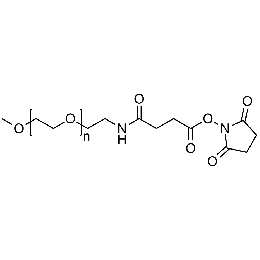

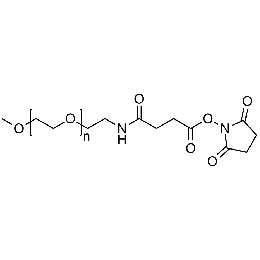

Methoxy PEG NHS, Mp 750Catalog Number 26064

Methoxy PEG NHS, Mp 750Catalog Number 26064 -

Methoxy PEG NHS, Mp 2000Catalog Number 26065

Methoxy PEG NHS, Mp 2000Catalog Number 26065 -

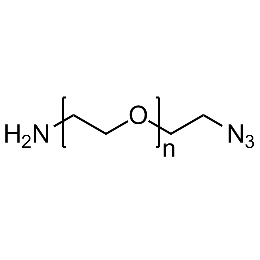

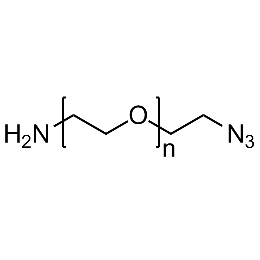

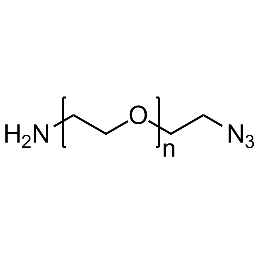

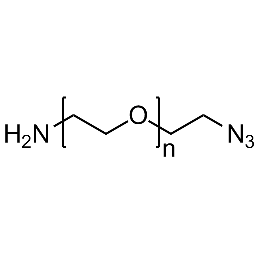

Amine PEG azide, Mp 3000Catalog Number 26248

Amine PEG azide, Mp 3000Catalog Number 26248 -

Methoxy PEG NHS, Mp 5000Catalog Number 26066

Methoxy PEG NHS, Mp 5000Catalog Number 26066 -

Methoxy PEG NHS, Mp 10000Catalog Number 26067

Methoxy PEG NHS, Mp 10000Catalog Number 26067 -

Methoxy PEG NHS, Mp 20000Catalog Number 26068

Methoxy PEG NHS, Mp 20000Catalog Number 26068 -

Amine PEG azide, Mp 5000Catalog Number 26249

Amine PEG azide, Mp 5000Catalog Number 26249 -

Amine PEG azide, Mp 10000Catalog Number 26250

Amine PEG azide, Mp 10000Catalog Number 26250 -

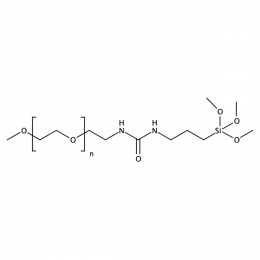

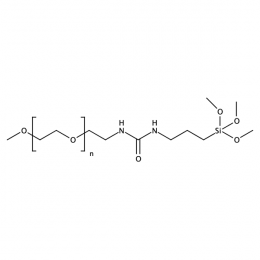

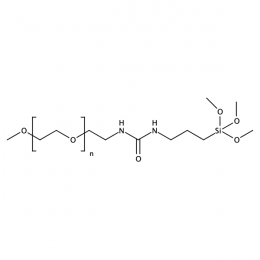

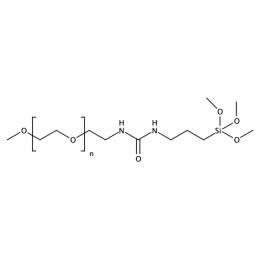

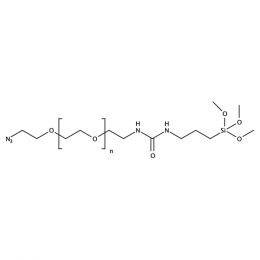

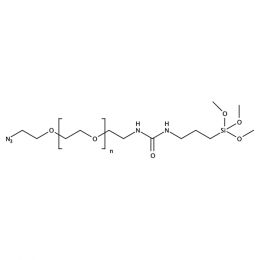

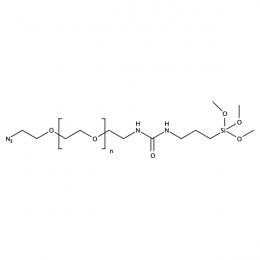

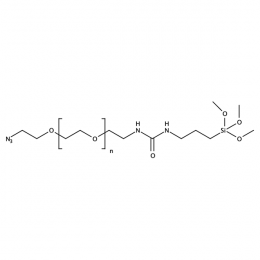

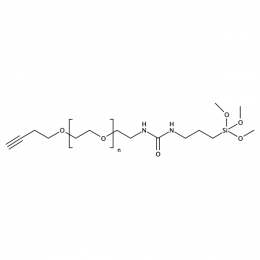

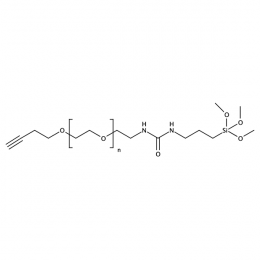

Methoxy PEG silane, Mp 2000Catalog Number 26069

Methoxy PEG silane, Mp 2000Catalog Number 26069 -

Methoxy PEG silane, Mp 5000Catalog Number 26070

Methoxy PEG silane, Mp 5000Catalog Number 26070 -

Methoxy PEG silane, Mp 10000Catalog Number 26071

Methoxy PEG silane, Mp 10000Catalog Number 26071 -

Methoxy PEG silane, Mp 20000Catalog Number 26072

Methoxy PEG silane, Mp 20000Catalog Number 26072 -

Amine PEG azide, Mp 20000Catalog Number 26251

Amine PEG azide, Mp 20000Catalog Number 26251 -

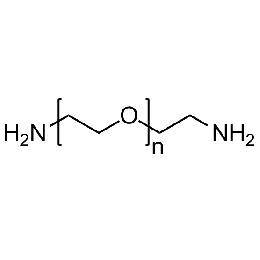

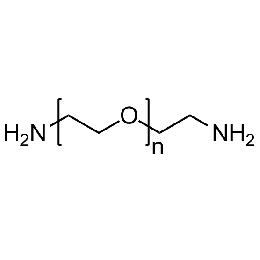

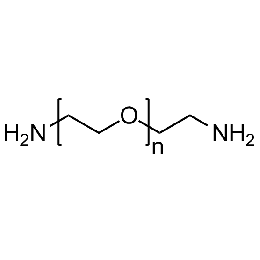

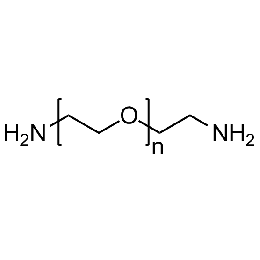

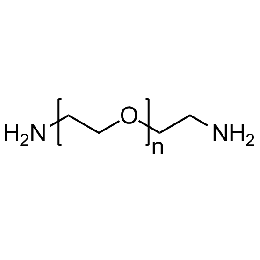

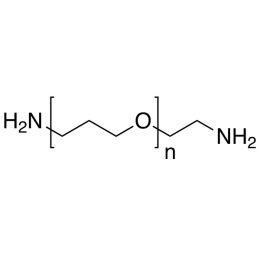

PEG diamine, Mp 2000Catalog Number 26078

PEG diamine, Mp 2000Catalog Number 26078 -

PEG diamine, Mp 3000Catalog Number 26079

PEG diamine, Mp 3000Catalog Number 26079 -

PEG diamine, Mp 6000Catalog Number 26080

PEG diamine, Mp 6000Catalog Number 26080 -

PEG diamine, Mp 10000Catalog Number 26081

PEG diamine, Mp 10000Catalog Number 26081 -

PEG diamine, Mp 20000Catalog Number 26082

PEG diamine, Mp 20000Catalog Number 26082 -

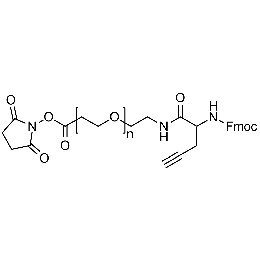

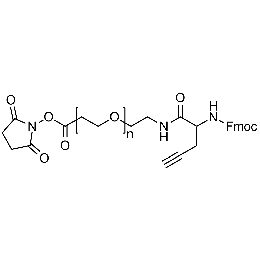

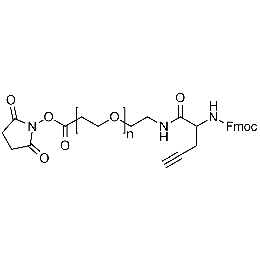

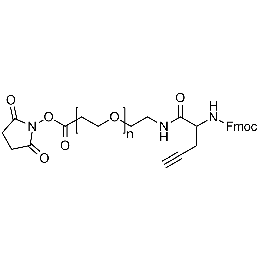

NHS PEG Fmoc-amine alkyne, Mp 20000Catalog Number 26247

NHS PEG Fmoc-amine alkyne, Mp 20000Catalog Number 26247 -

NHS PEG Fmoc-amine alkyne, Mp 10000Catalog Number 26246

NHS PEG Fmoc-amine alkyne, Mp 10000Catalog Number 26246 -

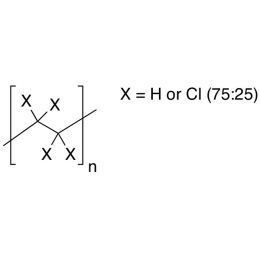

Polyethylene, chlorinated, 25% ClCatalog Number 01814

Polyethylene, chlorinated, 25% ClCatalog Number 01814Useful as primer or coating resin due to good adhesion properties. Randomly chlorinated HDPE.

-

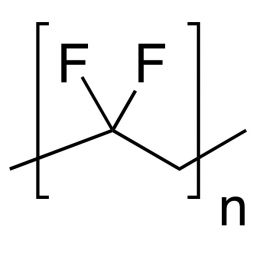

Poly(vinylidene fluoride)Catalog Number 18734

Poly(vinylidene fluoride)Catalog Number 18734Inert coating resin.

Polydispersity 2.5-3.0

-

Poly(chlorotrifluroethylene)Catalog Number 15176

Poly(chlorotrifluroethylene)Catalog Number 15176Inert liquid for high temperature baths.

-

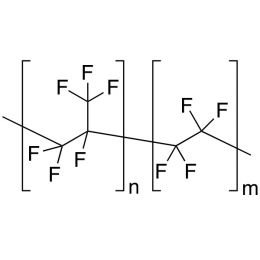

Fluorinated Ethylene Propylene Copolymer (Melt Flow Index 10-35 MI)Catalog Number 24778

Fluorinated Ethylene Propylene Copolymer (Melt Flow Index 10-35 MI)Catalog Number 24778Fluorinated copolymers of ethylene and propylene improve overall performance when formulated into plastics, elastomeric polymers, paints and coatings or inks and lubricants. Exhibits high release characteristics, excellent wear and mar resistance and slip resistance properties when used alone or in blends with other materials. The inherent toughness and high fluorine content imparts improved tear resistance, surface smoothness and flammability resistance in coating and ink formulations.

-

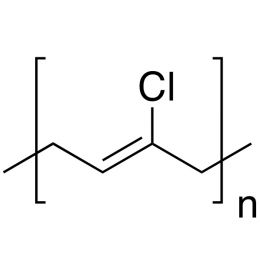

Poly(2-chloro-1,3-butadiene)Catalog Number 21289

Poly(2-chloro-1,3-butadiene)Catalog Number 21289Widely used rubber for applications requiring good solvent resistance.

Neoprene®

-

![Poly(2-hydroxyethyl methacrylate) [powder]](https://www.polysciences.com/media/catalog/product/cache/41caa8e834a03fb3ab31ba2c24269124/0/9/09689.jpg) Poly(2-hydroxyethyl methacrylate) [powder]Catalog Number 09689

Poly(2-hydroxyethyl methacrylate) [powder]Catalog Number 09689Polymer is water-insoluble but water-swellable. Used as a hydrogel. See 2-hydroxyethyl methacrylate Soluble in: 95% lower alcohols (5% water), DMF

-

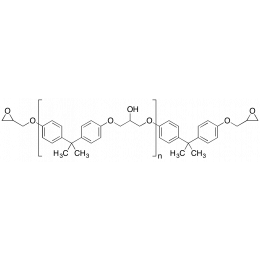

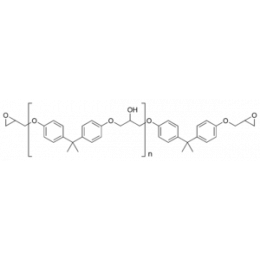

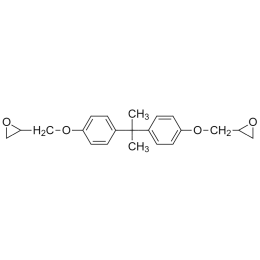

Epon® Resin 1001FCatalog Number 24305

Epon® Resin 1001FCatalog Number 24305(Bisphenol A diglycidyl ether) WPE: 525-550

Higher MW epoxy resin cured by amine catalyst, used for embedding.

-

Epon® Resin 828Catalog Number 02334

Epon® Resin 828Catalog Number 02334(Bisphenol A diglycidyl ether) WPE: 185-192

Epon® Resin 828 is a standard epoxy resin used in formulation, fabrication and fusion technology. Widely used for embedding and potting. When cross-linked or hardened with appropriate amine curing agents, very good mechanical adhesive, dielectric and chemical resistance properties are obtained.

-

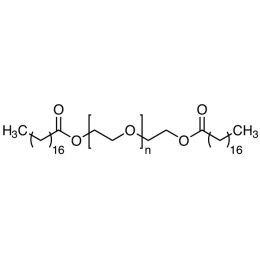

Poly(ethylene glycol) distearate 6,000Catalog Number 19234

Poly(ethylene glycol) distearate 6,000Catalog Number 19234A removable embedding medium for thin and thick sections. In thicker sections the exterior surface of mitochondria can be observed whereas in resin-embedded thin sections the mitochondria are most frequently observed in a cross section. DGD is used to prepare tissue for immunofluorescent localization of cytoskeletal components. Also used for tissue preparation for in-situ hybridization with nucleic acid probes.

MW = Molecular weight of PEG.

-

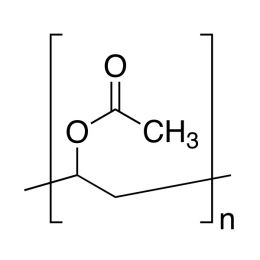

Ethylene-vinyl acetate, 20% ethylene, fine powderCatalog Number 24763

Ethylene-vinyl acetate, 20% ethylene, fine powderCatalog Number 24763Just add water to this solid grade polymer and it quickly responds by dispersing into latex particles that are useful bonding agents in composites. After evaporation of the water, a solid article may be formed from admixtures of the polymer and other solid components.

-

![Poly[methylene(polyphenyl) isocyanate]](https://www.polysciences.com/media/catalog/product/cache/41caa8e834a03fb3ab31ba2c24269124/0/3/03099_1.jpg) Poly[methylene(polyphenyl) isocyanate]Catalog Number 03099

Poly[methylene(polyphenyl) isocyanate]Catalog Number 03099Low molecular weight polyisocyanate, reacts with glycols, polyamines to form gels.

Soluble in: acetone, THF, toluene

NCO content ~30%

-

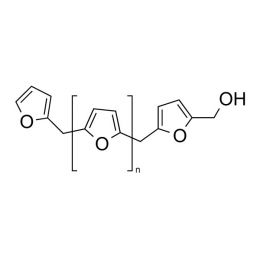

Poly(furfuryl alcohol)Catalog Number 15794

Poly(furfuryl alcohol)Catalog Number 15794Dark, viscous, fluid with double bonds in the polymer backbone.

-

![Polybutadiene [MW 1,600]](https://www.polysciences.com/media/catalog/product/cache/41caa8e834a03fb3ab31ba2c24269124/2/2/22395_1.jpg) Polybutadiene [MW 1,600]Catalog Number 22395

Polybutadiene [MW 1,600]Catalog Number 22395Liquid polyene that can be cured with sulfur or peroxides.

1,2-vinyl content: 80%

-

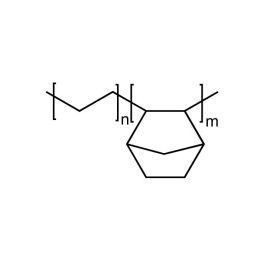

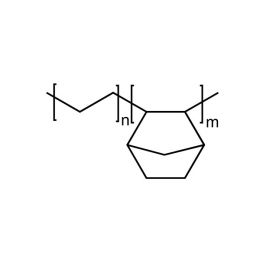

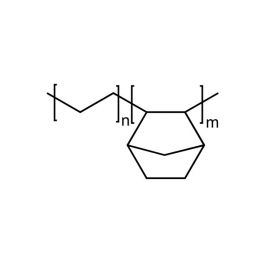

Cyclic Olefin Copolymer, HDT= 170°CCatalog Number 24746

Cyclic Olefin Copolymer, HDT= 170°CCatalog Number 24746Cyclic Olefin Copolymers are high transparency, low specific gravity, high heat resistant and have excellent optical properties and superior water vapor barrier characteristics. Combined with outstanding stiffness/ strength and favorable sterilization properties, they have found applications ranging from FDA approvals for pharmaceutical and food applications to optical applications and electronics materials. Whether used by itself or as a modifier for other resins, the ethylene-norbornene copolymer offers the optical clarity of polymethylmethacryate (pMMA), the heat resistance of polycarbonate (PC) and superior dimensional stability.

-

Cyclic Olefin Copolymer, HDT= 130°CCatalog Number 24749Inquire for availability.Phone: 1(800)523-2575Email: [email protected]

Cyclic Olefin Copolymer, HDT= 130°CCatalog Number 24749Inquire for availability.Phone: 1(800)523-2575Email: [email protected]Cyclic Olefin Copolymers are high transparency, low specific gravity, high heat resistant and have excellent optical properties and superior water vapor barrier characteristics. Combined with outstanding stiffness/ strength and favorable sterilization properties, they have found applications ranging from FDA approvals for pharmaceutical and food applications to optical applications and electronics materials. Whether used by itself or as a modifier for other resins, the ethylene-norbornene copolymer offers the optical clarity of polymethylmethacryate (pMMA), the heat resistance of polycarbonate (PC) and superior dimensional stability.

Applications:

-

Cyclic Olefin Copolymer, HDT= 75°CCatalog Number 24750

Cyclic Olefin Copolymer, HDT= 75°CCatalog Number 24750Cyclic Olefin Copolymers are high transparency, low specific gravity, high heat resistant and have excellent optical properties and superior water vapor barrier characteristics. Combined with outstanding stiffness/ strength and favorable sterilization properties, they have found applications ranging from FDA approvals for pharmaceutical and food applications to optical applications and electronics materials. Whether used by itself or as a modifier for other resins, the ethylene-norbornene copolymer offers the optical clarity of polymethylmethacryate (pMMA), the heat resistance of polycarbonate (PC) and superior dimensional stability.

-

![Polybutadiene [MW 3,000]](https://www.polysciences.com/media/catalog/product/cache/41caa8e834a03fb3ab31ba2c24269124/0/6/06081_1.jpg) Polybutadiene [MW 3,000]Catalog Number 06081

Polybutadiene [MW 3,000]Catalog Number 06081Liquid polyene that can be cured with sulfur or peroxides

liquid vinyl-1,2=80%

-

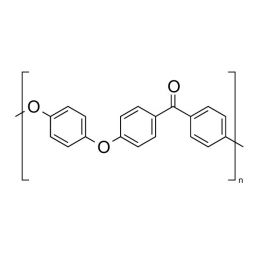

Poly ether ether ketone (PEEK)Catalog Number 23969

Poly ether ether ketone (PEEK)Catalog Number 23969High Temperature Resistant Polymer

Granules are dusted with a nominal 0.01% Calcium Stearate as a processing lubricant

-

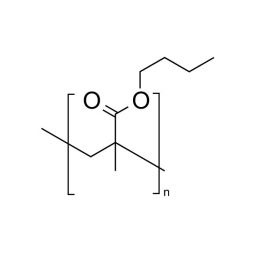

Poly(n-butyl methacrylate)Catalog Number 02061

Poly(n-butyl methacrylate)Catalog Number 02061Firm, water-insensitive, polymer.

- [η] = 0.50

- purity >95% polymer

-

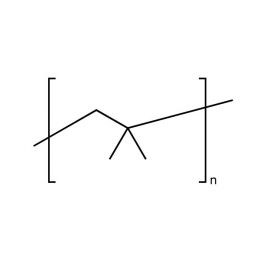

PolyisobutyleneCatalog Number 09894Inquire for availability.Phone: 1(800)523-2575Email: [email protected]

PolyisobutyleneCatalog Number 09894Inquire for availability.Phone: 1(800)523-2575Email: [email protected]Generally inert, tacky, polymers. Primarily used as tackifying agent in polymer formulations

-

![Polyisobutylene [MW 1,350]](https://www.polysciences.com/media/catalog/product/cache/41caa8e834a03fb3ab31ba2c24269124/0/9/09896_1.jpg) Polyisobutylene [MW 1,350]Catalog Number 09896

Polyisobutylene [MW 1,350]Catalog Number 09896Generally inert, tacky, polymers. Primarily used as tackifying agent in polymer formulations.

-

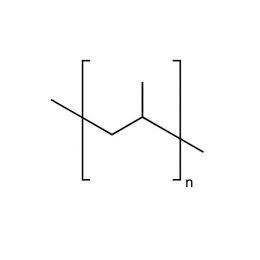

Polypropylene, IsotacticCatalog Number 06536

Polypropylene, IsotacticCatalog Number 06536Widely used polyolefin.

Soluble in: chlorinated hydrocarbons, aromatic hydrocarbons, isoamyl acetate.

Isotactic Mn 40,000 flakes

-

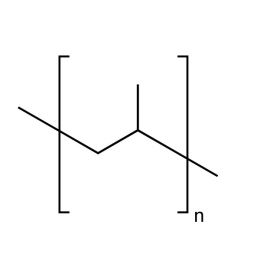

PolypropyleneCatalog Number 23968

PolypropyleneCatalog Number 23968Widely used polyolefin.

Atactic

-

PolyethyleneCatalog Number 07652Inquire for availability.Phone: 1(800)523-2575Email: [email protected]

PolyethyleneCatalog Number 07652Inquire for availability.Phone: 1(800)523-2575Email: [email protected]Hydrophobic, easily processed or fabricated, resin

Soluble in: xylene, tetralin, TCE @ 50-60°

Mw/Mn = 1.10

lumps

-

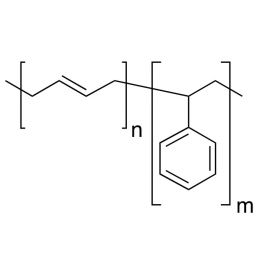

Poly(styrene/butadiene) 85:15Catalog Number 07073

Poly(styrene/butadiene) 85:15Catalog Number 07073Rubber modifier, random copolymer.

-

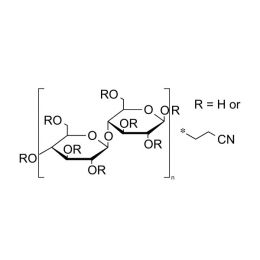

Cellulose, cyanoethyl etherCatalog Number 04687

Cellulose, cyanoethyl etherCatalog Number 04687Solvent-soluble cellulose ether. Soluble in polar solvents. High dielectric constant.

-

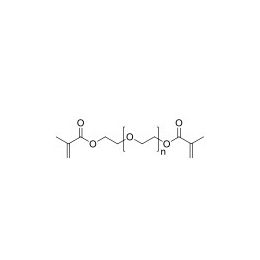

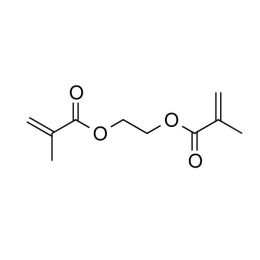

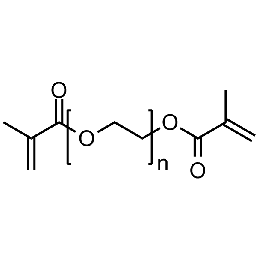

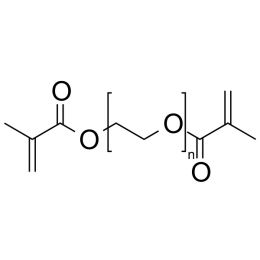

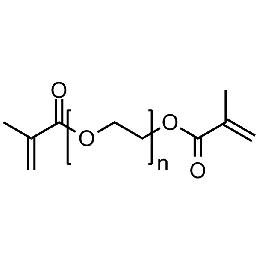

Polyethylene glycol dimethacrylate (PEGDMA 600)Catalog Number 02364

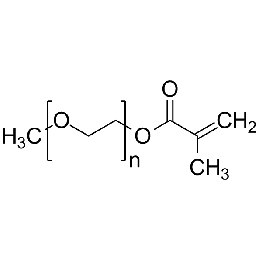

Polyethylene glycol dimethacrylate (PEGDMA 600)Catalog Number 02364Long-chain hydrophilic, crosslinking monomer. Molecular weight of PEG unit is approximately 600.

-

Polyethylene glycol dimethacrylate (PEGDMA 200)Catalog Number 00096

Polyethylene glycol dimethacrylate (PEGDMA 200)Catalog Number 00096Long-chain hydrophilic, crosslinking monomer. Molecular weight of PEG unit is approximately 200.

-

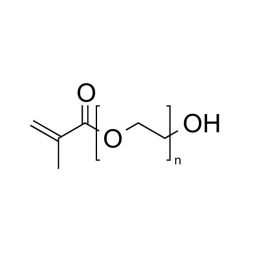

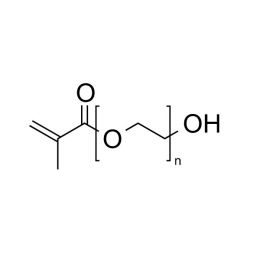

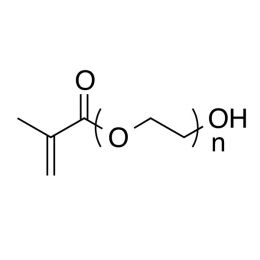

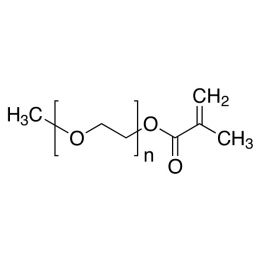

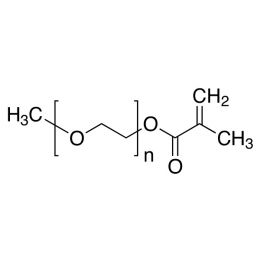

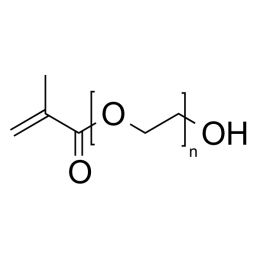

Polyethylene glycol monomethacrylate (PEGMA 200)Catalog Number 16712

Polyethylene glycol monomethacrylate (PEGMA 200)Catalog Number 16712Long-chain hydrophilic macromonomers. Used to introduce hydrophilic sites into polymers, to stabilize emulsion polymers, and to prepare comb polymers. (n) value is MW of PEG unit.

n= 200 (MW of PEG Block= 200)

-

Polyethylene glycol monomethacrylate (PEGMA 400)Catalog Number 16713

Polyethylene glycol monomethacrylate (PEGMA 400)Catalog Number 16713PEGMA 400 (HO-PEG-MA 400) is a long-chain hydrophilic macromonomer used to introduce hydrophilic sites into polymers, to stabilize emulsion polymers, and to prepare comb polymers.

MW of PEG Block = 400

-

Parafilm, 4" x 250' per rollCatalog Number 3989A

Parafilm, 4" x 250' per rollCatalog Number 3989AUsed for sealing or protecting vessels such as flasks or cuvettes. Molds quickly and seals laboratory vessels with a disposable translucent film. Parafilm is stretchable, moldable, waterproof, odorless, thermoplastic and self-adhering.

-

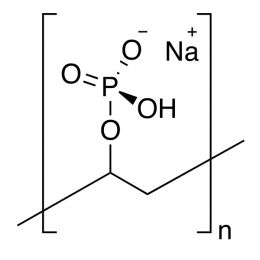

Poly(vinyl phosphoric acid), sodium saltCatalog Number 04391

Poly(vinyl phosphoric acid), sodium saltCatalog Number 04391Water-soluble polymeric phosphate ester. Uncrosslinked.

Phosphorous content min 5%

-

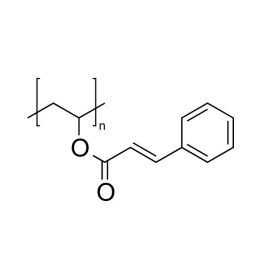

Poly(vinyl cinnamate)Catalog Number 02648

Poly(vinyl cinnamate)Catalog Number 02648Photocrosslinkable polymer.

-

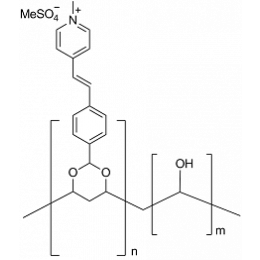

Poly(vinyl alcohol), N-methyl-4(4’-formylstyryl)pyridinium methosulfate acetalCatalog Number 22570

Poly(vinyl alcohol), N-methyl-4(4’-formylstyryl)pyridinium methosulfate acetalCatalog Number 22570Water-soluble, photocrosslinkable polymer. Polymer has high dielectric constant. Commercially used for making screen-printing emulsions for direct and direct/indirect methods.

Other applications include non-silver films such as contact films, color proofing, deep-etch plates, color filters, suitable for UV curable films for biomedical coatings.

13.3% solution in water. 10g polymer PVA-SbQ 4.1 mol % SbQ

-

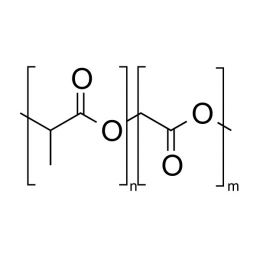

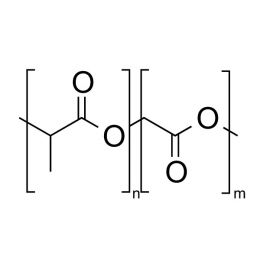

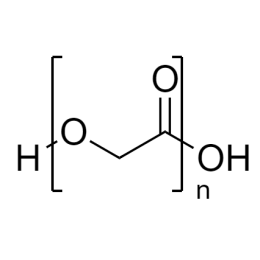

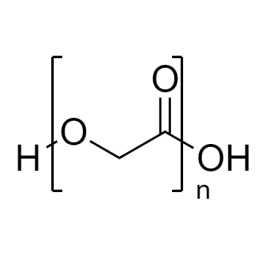

Poly(D,L-lactide-co-glycolide), 90:10, IV 0.2 dl/gCatalog Number 19076

Poly(D,L-lactide-co-glycolide), 90:10, IV 0.2 dl/gCatalog Number 19076Biodegradable polymers. Copolymers are easier to fabricate than homopolymers.

-

Poly(D,L-lactide-co-glycolide), 85:15, IV 0.85 dL/gCatalog Number 23989

Poly(D,L-lactide-co-glycolide), 85:15, IV 0.85 dL/gCatalog Number 23989Biodegradable polymers. Copolymers are easier to fabricate than homopolymers.

Soluble in: MDC, THF, ethyl acetate, acetone

85/15 i.v. 0.55-0.75

-

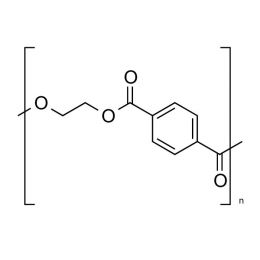

Poly(ethylene glycol terephthalate)Catalog Number 04301

Poly(ethylene glycol terephthalate)Catalog Number 04301Polymer widely used in films, fibers, and drink bottles. Low gas permeability.

(PET)

-

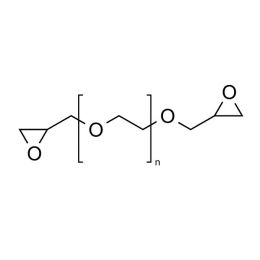

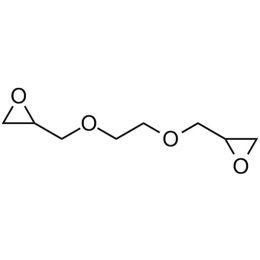

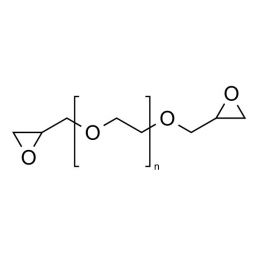

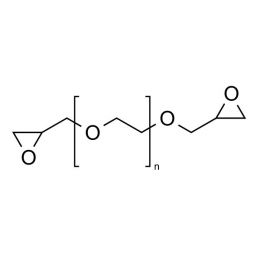

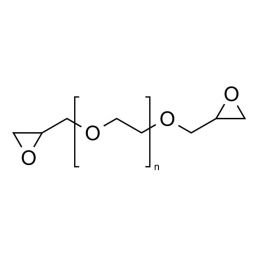

Poly(ethylene glycol) diglycidyl ether (PEGDGE 1000)Catalog Number 24047Poly(ethylene glycol) diglycidyl ether (n ~22; also known as PEGDE) is a difunctional, water-soluble crosslinker for amine-, hydroxyl-, and carboxyl-functional polymers.

Poly(ethylene glycol) diglycidyl ether (PEGDGE 1000)Catalog Number 24047Poly(ethylene glycol) diglycidyl ether (n ~22; also known as PEGDE) is a difunctional, water-soluble crosslinker for amine-, hydroxyl-, and carboxyl-functional polymers. -

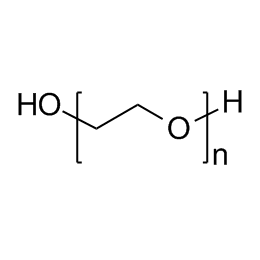

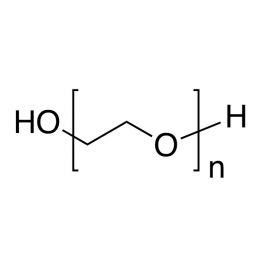

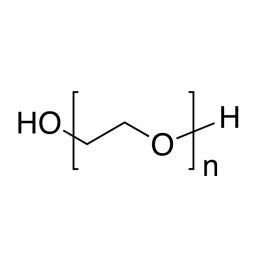

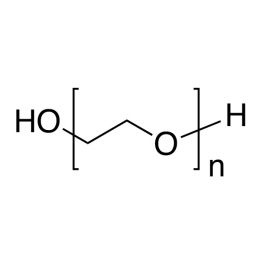

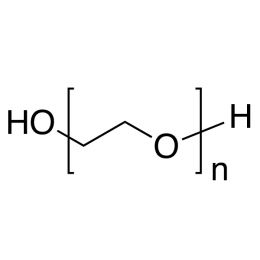

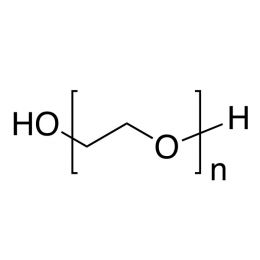

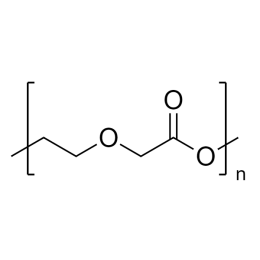

Poly(ethylene glycol) MW 2,000Catalog Number 25360

Poly(ethylene glycol) MW 2,000Catalog Number 25360Water-soluble, nonionic, relatively inert, liquids or solids. Confers slip and humectant properties to coatings. See poly(ethylene oxide) for higher molecular weights. The terms poly(ethylene glycol) and poly(ethylene oxide) refer to polymers which are chemically identical. Polymer chains are hydroxyl-terminated at both ends. At all except the lowest molecular weights poly(ethylene glycol) has a broad molecular weight distribution ranging from ~ 0.5x to 1.5x the values shown.

-

![Poly(ethylene glycol) [MW 1,450]](https://www.polysciences.com/media/catalog/product/cache/41caa8e834a03fb3ab31ba2c24269124/0/0/00679.jpg) Poly(ethylene glycol) [MW 1,450]Catalog Number 00679Inquire for availability.Phone: 1(800)523-2575Email: [email protected]

Poly(ethylene glycol) [MW 1,450]Catalog Number 00679Inquire for availability.Phone: 1(800)523-2575Email: [email protected]Water-soluble, nonionic, relatively inert, liquids or solids. Confers slip and humectant properties to coatings. See poly(ethylene oxide) for higher molecular weights. The terms poly(ethylene glycol) and poly(ethylene oxide) refer to polymers which are chemically identical. Polymer chains are hydroxyl-terminated at both ends. At all except the lowest molecular weights poly(ethylene glycol) has a broad molecular weight distribution ranging from ~ 0.5x to 1.5x the values shown.

PEG

-

![Poly(ethylene glycol) [MW 600]](https://www.polysciences.com/media/catalog/product/cache/41caa8e834a03fb3ab31ba2c24269124/0/0/00684.jpg) Poly(ethylene glycol) [MW 600]Catalog Number 00684

Poly(ethylene glycol) [MW 600]Catalog Number 00684Water-soluble, nonionic, relatively inert, liquids or solids. Confers slip and humectant properties to coatings. See poly(ethylene oxide) for higher molecular weights. The terms poly(ethylene glycol) and poly(ethylene oxide) refer to polymers which are chemically identical. Polymer chains are hydroxyl-terminated at both ends. At all except the lowest molecular weights poly(ethylene glycol) has a broad molecular weight distribution ranging from ~ 0.5x to 1.5x the values shown.

-

Poly(ethylene glycol), MW 400 (PEG 400)Catalog Number 01109

Poly(ethylene glycol), MW 400 (PEG 400)Catalog Number 01109Water-soluble, nonionic, relatively inert, liquids or solids. Confers slip and humectant properties to coatings. See poly(ethylene oxide) for higher molecular weights. The terms poly(ethylene glycol) and poly(ethylene oxide) refer to polymers which are chemically identical. Polymer chains are hydroxyl-terminated at both ends. At all except the lowest molecular weights poly(ethylene glycol) has a broad molecular weight distribution ranging from ~ 0.5x to 1.5x the values shown.

Soluble in: alcohol, acetone, chloroform, toluene, dichloromethane

-

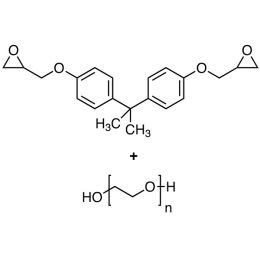

Poly(ethylene glycol)-bisphenol A diglycidyl ether adductCatalog Number 04686

Poly(ethylene glycol)-bisphenol A diglycidyl ether adductCatalog Number 04686Polymer contains more hydroxyl groups (4 or more) than poly(ethylene glycol)

-

Poly(ethylene glycol), MW 3400, pharma grade (PEG 3400)Catalog Number 06102

Poly(ethylene glycol), MW 3400, pharma grade (PEG 3400)Catalog Number 06102Water-soluble, nonionic, relatively inert, liquids or solids. Confers slip and humectant properties to coatings. See poly(ethylene oxide) for higher molecular weights. The terms poly(ethylene glycol) and poly(ethylene oxide) refer to polymers which are chemically identical. Polymer chains are hydroxyl-terminated at both ends. At all except the lowest molecular weights poly(ethylene glycol) has a broad molecular weight distribution ranging from ~ 0.5x to 1.5x the values shown.

PEG

-

Poly(ethylene glycol), MW 7,500 (PEG 7500)Catalog Number 06103

Poly(ethylene glycol), MW 7,500 (PEG 7500)Catalog Number 06103Water-soluble, nonionic, relatively inert, liquids or solids. Confers slip and humectant properties to coatings. See poly(ethylene oxide) for higher molecular weights. The terms poly(ethylene glycol) and poly(ethylene oxide) refer to polymers which are chemically identical. Polymer chains are hydroxyl-terminated at both ends. At all except the lowest molecular weights poly(ethylene glycol) has a broad molecular weight distribution ranging from ~ 0.5x to 1.5x the values shown.

Soluble in: alcohol, acetone, chloroform, toluene, dichloromethane

PEG

-

Poly(ethylene glycol), MW 10,000-16,000 (PEG 10K-16K)Catalog Number 22567

Poly(ethylene glycol), MW 10,000-16,000 (PEG 10K-16K)Catalog Number 22567Water-soluble, nonionic, relatively inert, liquids or solids. Confers slip and humectant properties to coatings. See poly(ethylene oxide) for higher molecular weights. The terms poly(ethylene glycol) and poly(ethylene oxide) refer to polymers which are chemically identical. Polymer chains are hydroxyl-terminated at both ends. At all except the lowest molecular weights poly(ethylene glycol) has a broad molecular weight distribution ranging from ~ 0.5x to 1.5x the values shown.

Soluble in: alcohol, acetone, chloroform, toluene, dichloromethane

PEG

-

![Poly(ethylene glycol) [MW 20,000]](https://www.polysciences.com/media/catalog/product/cache/41caa8e834a03fb3ab31ba2c24269124/2/2/22568.jpg) Poly(ethylene glycol) [MW 20,000]Catalog Number 22568

Poly(ethylene glycol) [MW 20,000]Catalog Number 22568Water-soluble, nonionic, relatively inert, liquids or solids. Confers slip and humectant properties to coatings. See poly(ethylene oxide) for higher molecular weights. The terms poly(ethylene glycol) and poly(ethylene oxide) refer to polymers which are chemically identical. Polymer chains are hydroxyl-terminated at both ends. At all except the lowest molecular weights poly(ethylene glycol) has a broad molecular weight distribution ranging from ~ 0.5x to 1.5x the values shown.

Soluble in: alcohol, acetone, chloroform, toluene, dichloromethane

PEG

-

![Poly(ethylene glycol) [MW 8000; pharma grade]](https://www.polysciences.com/media/catalog/product/cache/41caa8e834a03fb3ab31ba2c24269124/1/7/17243.jpg) Poly(ethylene glycol) [MW 8000; pharma grade]Catalog Number 17243

Poly(ethylene glycol) [MW 8000; pharma grade]Catalog Number 17243Water-soluble, nonionic, relatively inert, liquids or solids. Confers slip and humectant properties to coatings. See poly(ethylene oxide) for higher molecular weights. The terms poly(ethylene glycol) and poly(ethylene oxide) refer to polymers which are chemically identical. Polymer chains are hydroxyl-terminated at both ends. At all except the lowest molecular weights poly(ethylene glycol) has a broad molecular weight distribution ranging from ~ 0.5x to 1.5x the values shown.

PEG

-

![Poly(ethylene glycol) [MW 1,000]](https://www.polysciences.com/media/catalog/product/cache/41caa8e834a03fb3ab31ba2c24269124/0/0/00682.jpg) Poly(ethylene glycol) [MW 1,000]Catalog Number 00682

Poly(ethylene glycol) [MW 1,000]Catalog Number 00682Water-soluble, nonionic, relatively inert, liquids or solids. Confers slip and humectant properties to coatings. See poly(ethylene oxide) for higher molecular weights. The terms poly(ethylene glycol) and poly(ethylene oxide) refer to polymers which are chemically identical. Polymer chains are hydroxyl-terminated at both ends. At all except the lowest molecular weights poly(ethylene glycol) has a broad molecular weight distribution ranging from ~ 0.5x to 1.5x the values shown.

Soluble in: alcohol, acetone, chloroform, toluene, dichloromethane

-

Poly(ethylene glycol) (200) adipateCatalog Number 21509

Poly(ethylene glycol) (200) adipateCatalog Number 21509Water-soluble, biodegradable, polymer. Reaction product of one molecule of adipic acid and two molecules of PEG 200

-

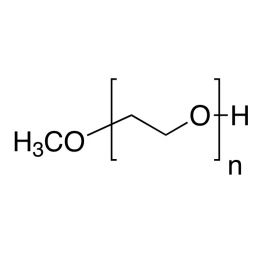

Poly(ethylene glycol) monomethyl etherCatalog Number 04457

Poly(ethylene glycol) monomethyl etherCatalog Number 04457Neutral, water-soluble, polymers with hydroxyl group at one end only

-

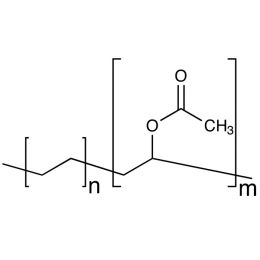

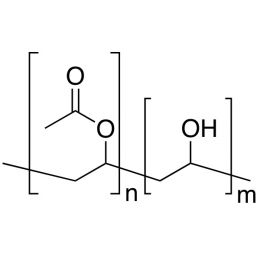

![Poly(ethylene/vinyl acetate) [60:40 (wt)]](https://www.polysciences.com/media/catalog/product/cache/41caa8e834a03fb3ab31ba2c24269124/0/6/06107_1.jpg) Poly(ethylene/vinyl acetate) [60:40 (wt)]Catalog Number 06107

Poly(ethylene/vinyl acetate) [60:40 (wt)]Catalog Number 06107Used as a hot-melt adhesive, wax additive, and precursor to poly (ethylene/vinyl alcohol) resins.

60:40 (wt) Antioxidant 540 ppm BHT

-

![Poly(ethylene/vinyl acetate) [72:28 (wt)]](https://www.polysciences.com/media/catalog/product/cache/41caa8e834a03fb3ab31ba2c24269124/0/6/06108_1.jpg) Poly(ethylene/vinyl acetate) [72:28 (wt)]Catalog Number 06108

Poly(ethylene/vinyl acetate) [72:28 (wt)]Catalog Number 06108Used as a hot-melt adhesive, wax additive, and precursor to poly (ethylene/vinyl alcohol) resins.

72:28 (wt))

-

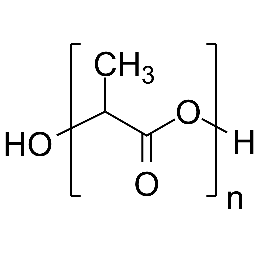

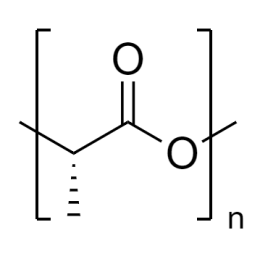

Poly(L-lactic acid), IV 1.8 dl/gCatalog Number 18402

Poly(L-lactic acid), IV 1.8 dl/gCatalog Number 18402Biodegradable polymer. Degradation rate is inversely related to polymer molecular weight.

Crystalline polymer with higher molecular weight polymers having a crystallinity of about 70%.

i.v. 1.30-1.60 Polydispersity ~1.8

-

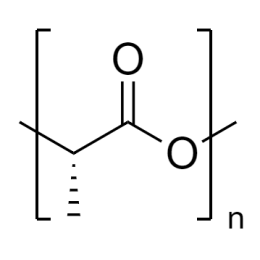

Poly(L-lactic acid), IV 5.0 dl/gCatalog Number 18582

Poly(L-lactic acid), IV 5.0 dl/gCatalog Number 18582Poly(L-lactide) (PLLA) is a biodegradable polymer for medical device and pharmaceutical applications. It is used to fabricate resorbable medical devices that degrade over months in physiological conditions. Due to their history, polylactides are one of the easiest and most affordable biodegradable polymers for medical devices.

-

Poly(L-lactic acid) Molecular Weight KitCatalog Number 18599

Poly(L-lactic acid) Molecular Weight KitCatalog Number 18599Biodegradable polymer. Degradation rate is inversely related to polymer molecular weight.

Kit contains:

5g each of polymers with i.v. values of:

- 0.10 - 0.20

- 0.80 - 1.20

- 1.30 - 1.60

- 4.00 - 5.20

-

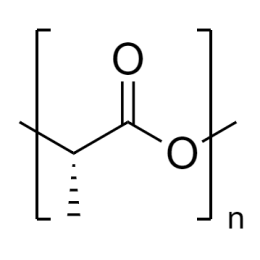

Poly(L-lactic acid), IV 6.5 dl/gCatalog Number 21512

Poly(L-lactic acid), IV 6.5 dl/gCatalog Number 21512Biodegradable polymer. Degradation rate is inversely related to polymer molecular weight.

Crystalline polymer with higher molecular weight polymers having a crystallinity of about 70%.

i.v. >7.00 Polydispersity ~1.8

-

NHS PEG Fmoc-amine alkyne, Mp 5000Catalog Number 26245

NHS PEG Fmoc-amine alkyne, Mp 5000Catalog Number 26245 -

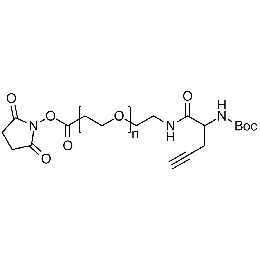

NHS PEG Fmoc-amine alkyne, Mp 3000Catalog Number 26244

NHS PEG Fmoc-amine alkyne, Mp 3000Catalog Number 26244 -

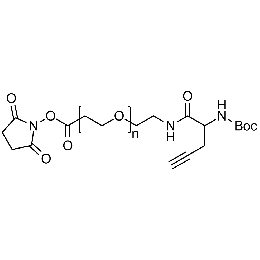

NHS PEG Boc-amine alkyne, Mp 20000Catalog Number 26243

NHS PEG Boc-amine alkyne, Mp 20000Catalog Number 26243 -

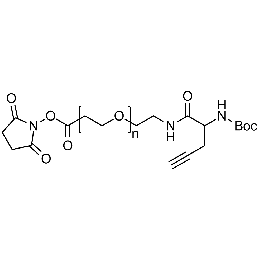

NHS PEG Boc-amine alkyne, Mp 10000Catalog Number 26242

NHS PEG Boc-amine alkyne, Mp 10000Catalog Number 26242 -

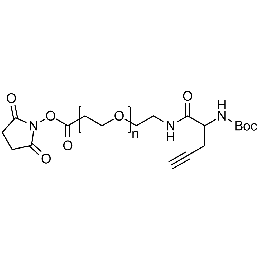

NHS PEG Boc-amine alkyne, Mp 5000Catalog Number 26241

NHS PEG Boc-amine alkyne, Mp 5000Catalog Number 26241 -

NHS PEG Boc-amine alkyne, Mp 3000Catalog Number 26240

NHS PEG Boc-amine alkyne, Mp 3000Catalog Number 26240 -

Silane PEG azide, MP 20000Catalog Number 26235

Silane PEG azide, MP 20000Catalog Number 26235 -

Silane PEG azide, MP 10000Catalog Number 26234

Silane PEG azide, MP 10000Catalog Number 26234 -

Silane PEG azide, MP 5000Catalog Number 26233

Silane PEG azide, MP 5000Catalog Number 26233 -

Silane PEG azide, MP 3000Catalog Number 26232

Silane PEG azide, MP 3000Catalog Number 26232 -

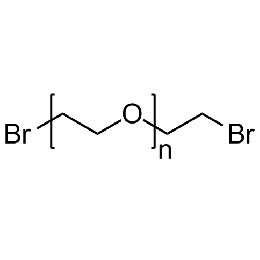

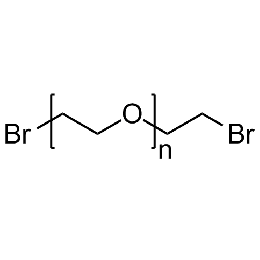

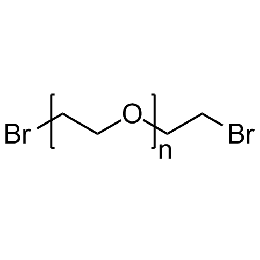

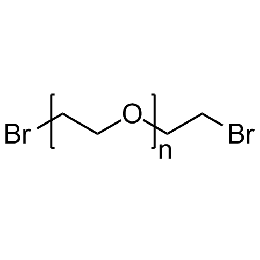

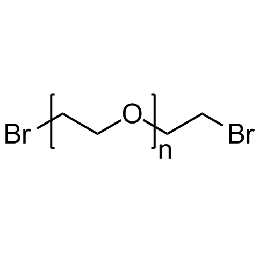

PEG dibromide, Mp 2000Catalog Number 26083

PEG dibromide, Mp 2000Catalog Number 26083 -

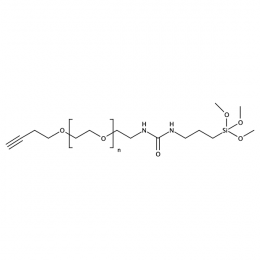

Silane PEG alkyne, MP 20000Catalog Number 26231

Silane PEG alkyne, MP 20000Catalog Number 26231 -

PEG dibromide, Mp 3000Catalog Number 26084

PEG dibromide, Mp 3000Catalog Number 26084 -

PEG dibromide, Mp 6000Catalog Number 26085

PEG dibromide, Mp 6000Catalog Number 26085 -

PEG dibromide, Mp 10000Catalog Number 26086

PEG dibromide, Mp 10000Catalog Number 26086 -

PEG dibromide, Mp 20000Catalog Number 26087

PEG dibromide, Mp 20000Catalog Number 26087 -

Silane PEG alkyne, MP 10000Catalog Number 26230

Silane PEG alkyne, MP 10000Catalog Number 26230 -

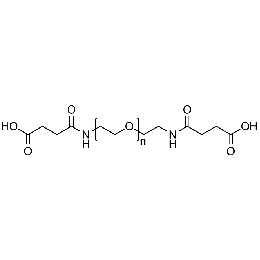

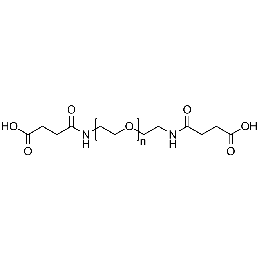

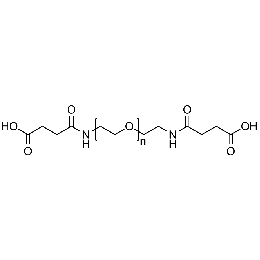

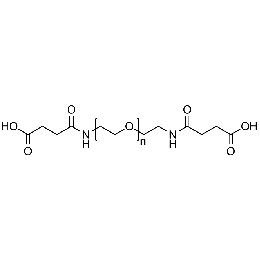

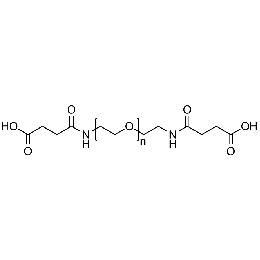

PEG di(carboxylic acid), Mp 2000Catalog Number 26088

PEG di(carboxylic acid), Mp 2000Catalog Number 26088 -

PEG di(carboxylic acid), Mp 3000Catalog Number 26089

PEG di(carboxylic acid), Mp 3000Catalog Number 26089 -

PEG di(carboxylic acid), Mp 6000Catalog Number 26090

PEG di(carboxylic acid), Mp 6000Catalog Number 26090 -

PEG di(carboxylic acid), Mp 10000Catalog Number 26091

PEG di(carboxylic acid), Mp 10000Catalog Number 26091 -

PEG di(carboxylic acid), Mp 20000Catalog Number 26092

PEG di(carboxylic acid), Mp 20000Catalog Number 26092 -

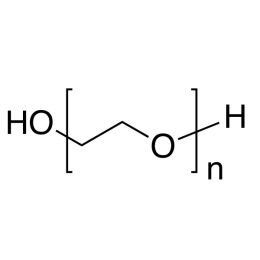

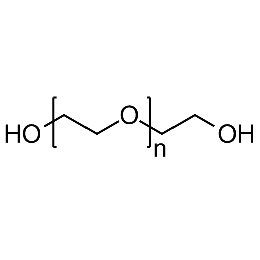

PEG dihydroxyl, Mp 2000Catalog Number 26098

PEG dihydroxyl, Mp 2000Catalog Number 26098 -

PEG dihydroxyl, Mp 3000Catalog Number 26099

PEG dihydroxyl, Mp 3000Catalog Number 26099 -

PEG dihydroxyl, Mp 6000Catalog Number 26100

PEG dihydroxyl, Mp 6000Catalog Number 26100 -

PEG dihydroxyl, Mp 10000Catalog Number 26101

PEG dihydroxyl, Mp 10000Catalog Number 26101 -

PEG dihydroxyl, Mp 20000Catalog Number 26102

PEG dihydroxyl, Mp 20000Catalog Number 26102 -

Silane PEG alkyne, MP 5000Catalog Number 26229

Silane PEG alkyne, MP 5000Catalog Number 26229 -

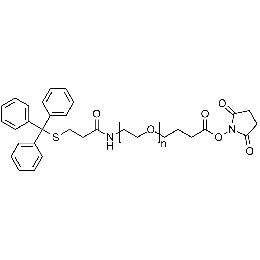

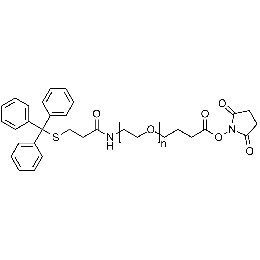

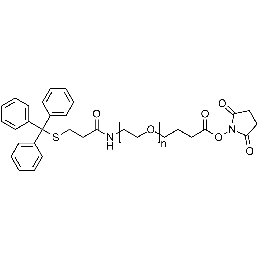

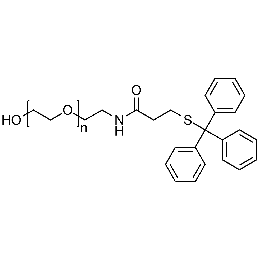

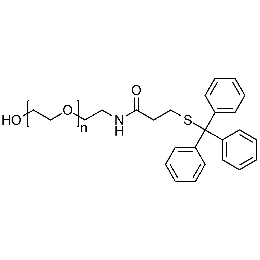

Tritythiol PEG NHS, MP 10000Catalog Number 26227

Tritythiol PEG NHS, MP 10000Catalog Number 26227 -

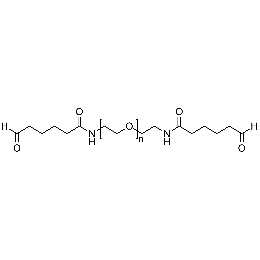

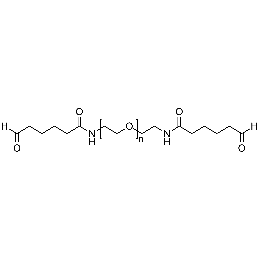

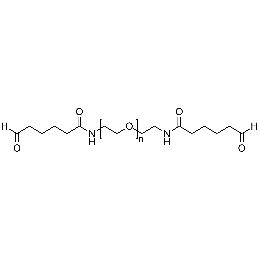

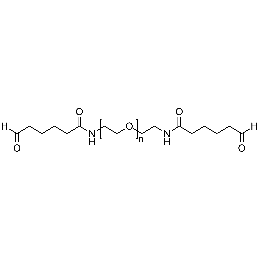

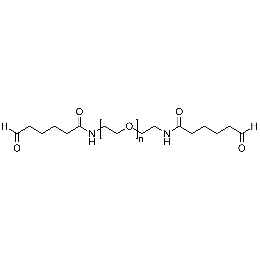

PEG dialdehyde, Mp 2000Catalog Number 26093

PEG dialdehyde, Mp 2000Catalog Number 26093 -

PEG dialdehyde, Mp 3000Catalog Number 26094

PEG dialdehyde, Mp 3000Catalog Number 26094 -

PEG dialdehyde, Mp 6000Catalog Number 26095

PEG dialdehyde, Mp 6000Catalog Number 26095 -

PEG dialdehyde, Mp 10000Catalog Number 26096

PEG dialdehyde, Mp 10000Catalog Number 26096 -

PEG dialdehyde, Mp 20000Catalog Number 26097

PEG dialdehyde, Mp 20000Catalog Number 26097 -

Tritythiol PEG NHS, MP 5000Catalog Number 26226

Tritythiol PEG NHS, MP 5000Catalog Number 26226 -

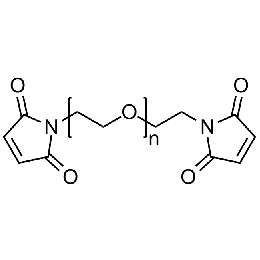

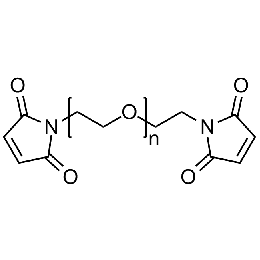

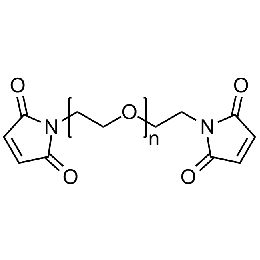

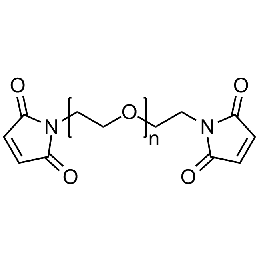

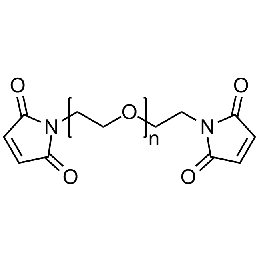

PEG dimaleimide, Mp 2000Catalog Number 26103

PEG dimaleimide, Mp 2000Catalog Number 26103 -

Tritythiol PEG NHS, MP 3000Catalog Number 26225

Tritythiol PEG NHS, MP 3000Catalog Number 26225 -

PEG dimaleimide, Mp 3000Catalog Number 26104

PEG dimaleimide, Mp 3000Catalog Number 26104 -

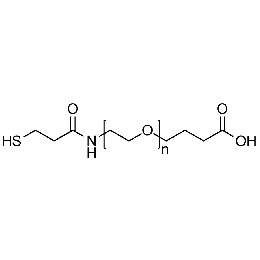

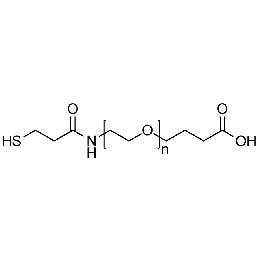

Thiol PEG carboxylic acid, Mp 10000Catalog Number 26224

Thiol PEG carboxylic acid, Mp 10000Catalog Number 26224 -

PEG dimaleimide, Mp 6000Catalog Number 26105

PEG dimaleimide, Mp 6000Catalog Number 26105 -

PEG dimaleimide, Mp 10000Catalog Number 26106

PEG dimaleimide, Mp 10000Catalog Number 26106 -

PEG dimaleimide, Mp 20000Catalog Number 26107

PEG dimaleimide, Mp 20000Catalog Number 26107 -

Thiol PEG carboxylic acid, Mp 5000Catalog Number 26223

Thiol PEG carboxylic acid, Mp 5000Catalog Number 26223 -

Thiol PEG carboxylic acid, Mp 3000Catalog Number 26222

Thiol PEG carboxylic acid, Mp 3000Catalog Number 26222 -

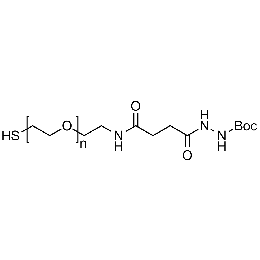

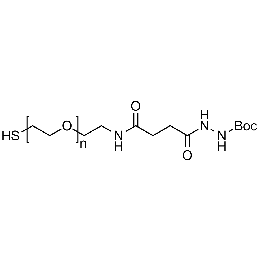

Thiol PEG Boc-hydrazine, Mp 10,000Catalog Number 26221

Thiol PEG Boc-hydrazine, Mp 10,000Catalog Number 26221 -

Thiol PEG Boc-hydrazine, Mp 5,000Catalog Number 26220

Thiol PEG Boc-hydrazine, Mp 5,000Catalog Number 26220 -

Thiol PEG Boc-hydrazine, Mp 3,000Catalog Number 26219

Thiol PEG Boc-hydrazine, Mp 3,000Catalog Number 26219 -

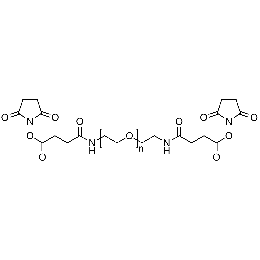

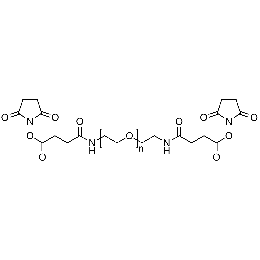

PEG di(NHS), Mp 2000Catalog Number 26113

PEG di(NHS), Mp 2000Catalog Number 26113 -

PEG di(NHS), Mp 3000Catalog Number 26114

PEG di(NHS), Mp 3000Catalog Number 26114 -

PEG di(NHS), Mp 6000Catalog Number 26115

PEG di(NHS), Mp 6000Catalog Number 26115 -

PEG di(NHS), Mp 10000Catalog Number 26116

PEG di(NHS), Mp 10000Catalog Number 26116 -

PEG di(NHS), Mp 20000Catalog Number 26117

PEG di(NHS), Mp 20000Catalog Number 26117 -

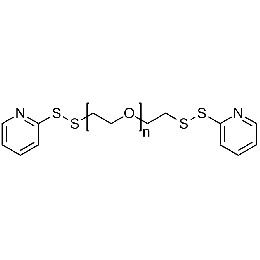

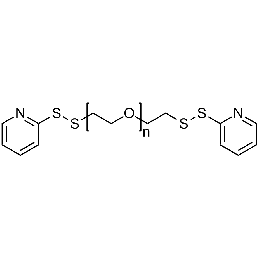

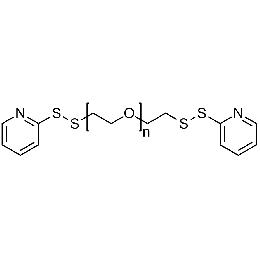

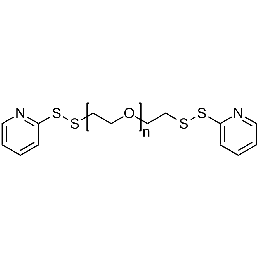

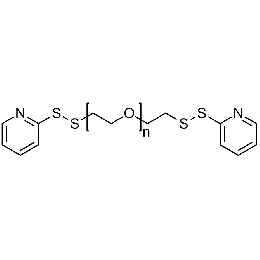

PEG di(OPSS), Mp 2000Catalog Number 26118

PEG di(OPSS), Mp 2000Catalog Number 26118 -

PEG di(OPSS), Mp 3000Catalog Number 26119

PEG di(OPSS), Mp 3000Catalog Number 26119 -

PEG di(OPSS), Mp 6000Catalog Number 26120

PEG di(OPSS), Mp 6000Catalog Number 26120 -

PEG di(OPSS), Mp 10000Catalog Number 26121

PEG di(OPSS), Mp 10000Catalog Number 26121 -

PEG di(OPSS), Mp 20000Catalog Number 26122

PEG di(OPSS), Mp 20000Catalog Number 26122 -

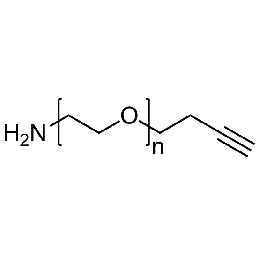

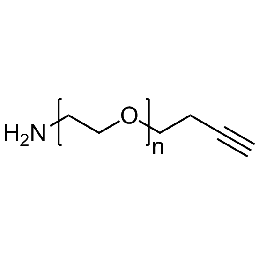

Amine PEG alkyne, Mp 3000Catalog Number 26123

Amine PEG alkyne, Mp 3000Catalog Number 26123 -

Amine PEG alkyne, Mp 5000Catalog Number 26124

Amine PEG alkyne, Mp 5000Catalog Number 26124 -

Amine PEG alkyne, Mp 10000Catalog Number 26125

Amine PEG alkyne, Mp 10000Catalog Number 26125 -

Amine PEG alkyne, Mp 20000Catalog Number 26126

Amine PEG alkyne, Mp 20000Catalog Number 26126 -

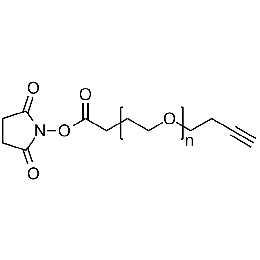

NHS PEG alkyne, Mp 3000Catalog Number 26127

NHS PEG alkyne, Mp 3000Catalog Number 26127 -

NHS PEG alkyne, Mp 5000Catalog Number 26128

NHS PEG alkyne, Mp 5000Catalog Number 26128 -

NHS PEG alkyne, Mp 10000Catalog Number 26129

NHS PEG alkyne, Mp 10000Catalog Number 26129 -

NHS PEG alkyne, Mp 20000Catalog Number 26130

NHS PEG alkyne, Mp 20000Catalog Number 26130 -

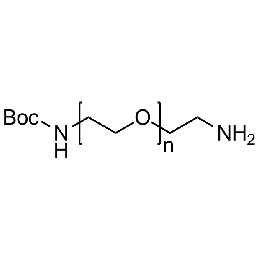

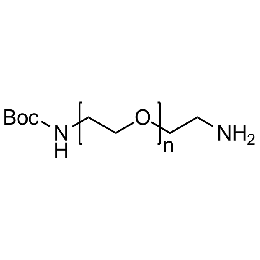

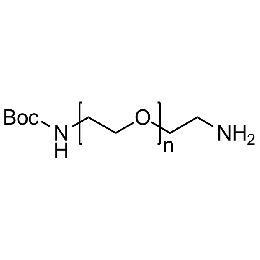

Amine PEG Boc-amine, Mp 3000Catalog Number 26131

Amine PEG Boc-amine, Mp 3000Catalog Number 26131 -

Amine PEG Boc-amine, Mp 5000Catalog Number 26132

Amine PEG Boc-amine, Mp 5000Catalog Number 26132 -

Amine PEG Boc-amine, Mp 10000Catalog Number 26133

Amine PEG Boc-amine, Mp 10000Catalog Number 26133 -

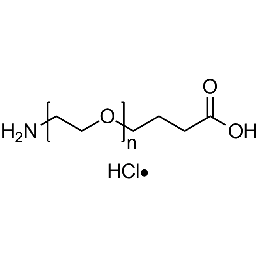

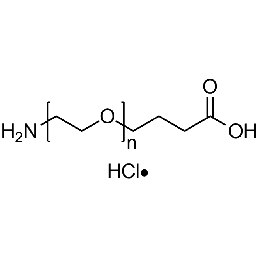

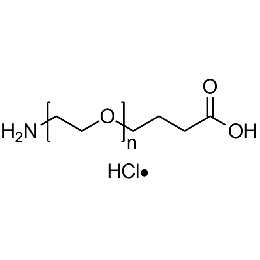

Amine PEG carboxylic acid hydrochloride, Mp 3000Catalog Number 26134

Amine PEG carboxylic acid hydrochloride, Mp 3000Catalog Number 26134 -

Amine PEG carboxylic acid hydrochloride, Mp 5000Catalog Number 26135

Amine PEG carboxylic acid hydrochloride, Mp 5000Catalog Number 26135 -

Amine PEG carboxylic acid hydrochloride, Mp 10000Catalog Number 26136

Amine PEG carboxylic acid hydrochloride, Mp 10000Catalog Number 26136 -

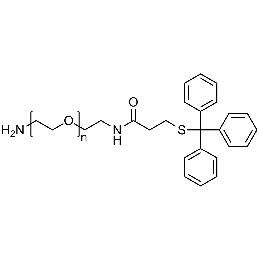

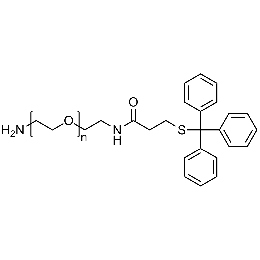

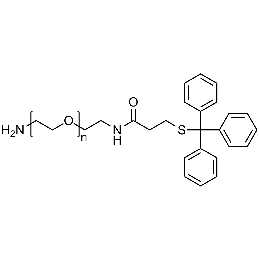

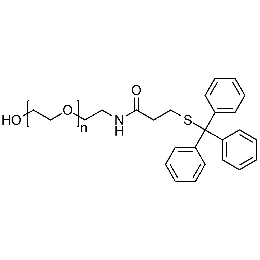

Amine PEG tritylthiol, Mp 3000Catalog Number 26137

Amine PEG tritylthiol, Mp 3000Catalog Number 26137 -

Amine PEG tritylthiol, Mp 5000Catalog Number 26138

Amine PEG tritylthiol, Mp 5000Catalog Number 26138 -

Amine PEG tritylthiol, Mp 10000Catalog Number 26139

Amine PEG tritylthiol, Mp 10000Catalog Number 26139 -

Hydroxyl PEG azide, Mp 3000Catalog Number 26140

Hydroxyl PEG azide, Mp 3000Catalog Number 26140 -

Hydroxyl PEG azide, Mp 5000Catalog Number 26141

Hydroxyl PEG azide, Mp 5000Catalog Number 26141 -

Hydroxyl PEG azide, Mp 10000Catalog Number 26142

Hydroxyl PEG azide, Mp 10000Catalog Number 26142 -

Hydroxyl PEG azide, Mp 20000Catalog Number 26143

Hydroxyl PEG azide, Mp 20000Catalog Number 26143 -

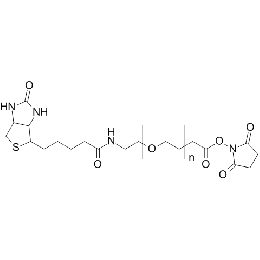

Biotin PEG carboxylic acid, Mp 3000Catalog Number 26147

Biotin PEG carboxylic acid, Mp 3000Catalog Number 26147 -

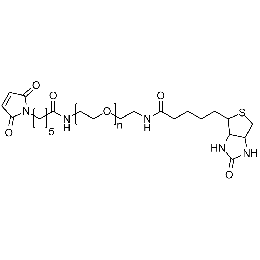

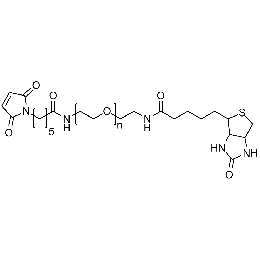

Biotin PEG amine, Mp 5000Catalog Number 26145

Biotin PEG amine, Mp 5000Catalog Number 26145 -

Biotin PEG amine, Mp 10000Catalog Number 26146

Biotin PEG amine, Mp 10000Catalog Number 26146 -

Biotin PEG carboxylic acid, Mp 5000Catalog Number 26148

Biotin PEG carboxylic acid, Mp 5000Catalog Number 26148 -

Biotin PEG amine, Mp 3000Catalog Number 26144

Biotin PEG amine, Mp 3000Catalog Number 26144 -

Biotin PEG NHS, Mp 3000Catalog Number 26150

Biotin PEG NHS, Mp 3000Catalog Number 26150 -

Biotin PEG NHS, Mp 5000Catalog Number 26151

Biotin PEG NHS, Mp 5000Catalog Number 26151 -

Biotin PEG NHS, Mp 10000Catalog Number 26152

Biotin PEG NHS, Mp 10000Catalog Number 26152 -

Biotin PEG thiol, Mp 3000Catalog Number 26153

Biotin PEG thiol, Mp 3000Catalog Number 26153 -

Biotin PEG thiol, Mp 5000Catalog Number 26154

Biotin PEG thiol, Mp 5000Catalog Number 26154 -

Biotin PEG thiol, Mp 10000Catalog Number 26155

Biotin PEG thiol, Mp 10000Catalog Number 26155 -

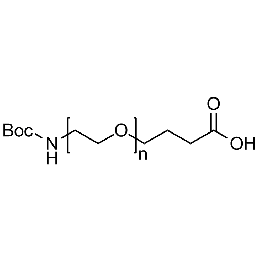

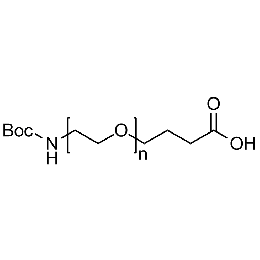

Boc-amine PEG carboxylic acid, Mp 3000Catalog Number 26156

Boc-amine PEG carboxylic acid, Mp 3000Catalog Number 26156 -

Boc-amine PEG carboxylic acid, Mp 5000Catalog Number 26157

Boc-amine PEG carboxylic acid, Mp 5000Catalog Number 26157 -

Boc-amine PEG carboxylic acid, Mp 10000Catalog Number 26158

Boc-amine PEG carboxylic acid, Mp 10000Catalog Number 26158 -

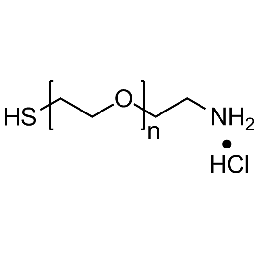

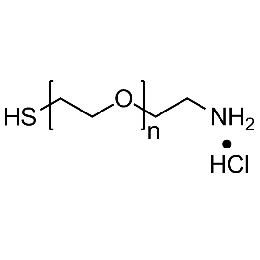

Thiol PEG amine hydrochloride, Mp 10000Catalog Number 26218

Thiol PEG amine hydrochloride, Mp 10000Catalog Number 26218 -

Thiol PEG amine hydrochloride, Mp 5000Catalog Number 26217

Thiol PEG amine hydrochloride, Mp 5000Catalog Number 26217 -

Thiol PEG amine hydrochloride, Mp 3000Catalog Number 26216

Thiol PEG amine hydrochloride, Mp 3000Catalog Number 26216 -

NHS PEG OPSS, MP 20,000Catalog Number 26215

NHS PEG OPSS, MP 20,000Catalog Number 26215 -

Biotin PEG OPSS, MP 20,000Catalog Number 26211

Biotin PEG OPSS, MP 20,000Catalog Number 26211 -

Boc-amine PEG thiol, Mp 3000Catalog Number 26159

Boc-amine PEG thiol, Mp 3000Catalog Number 26159 -

Boc-amine PEG thiol, Mp 5000Catalog Number 26160

Boc-amine PEG thiol, Mp 5000Catalog Number 26160 -

Boc-amine PEG thiol, Mp 10000Catalog Number 26161

Boc-amine PEG thiol, Mp 10000Catalog Number 26161 -

NHS PEG OPSS, MP 5,000Catalog Number 26213

NHS PEG OPSS, MP 5,000Catalog Number 26213 -

NHS PEG OPSS, MP 3,000Catalog Number 26212

NHS PEG OPSS, MP 3,000Catalog Number 26212 -

Biotin PEG OPSS, MP 10,000Catalog Number 26210

Biotin PEG OPSS, MP 10,000Catalog Number 26210 -

Boc-amine PEG NHS, Mp 3000Catalog Number 26162

Boc-amine PEG NHS, Mp 3000Catalog Number 26162 -

Boc-amine PEG NHS, Mp 5000Catalog Number 26163

Boc-amine PEG NHS, Mp 5000Catalog Number 26163 -

Boc-amine PEG NHS, Mp 10000Catalog Number 26164

Boc-amine PEG NHS, Mp 10000Catalog Number 26164 -

Biotin PEG OPSS, MP 3,000Catalog Number 26208

Biotin PEG OPSS, MP 3,000Catalog Number 26208 -

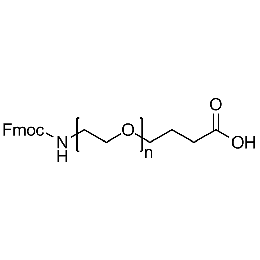

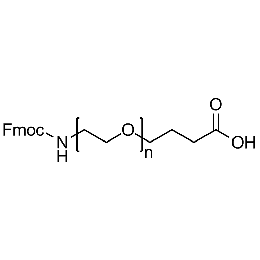

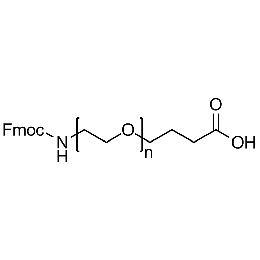

Fmoc-amine PEG carboxylic acid, Mp 3000Catalog Number 26165

Fmoc-amine PEG carboxylic acid, Mp 3000Catalog Number 26165 -

Fmoc-amine PEG carboxylic acid, Mp 5000Catalog Number 26166

Fmoc-amine PEG carboxylic acid, Mp 5000Catalog Number 26166 -

Fmoc-amine PEG carboxylic acid, Mp 10000Catalog Number 26167

Fmoc-amine PEG carboxylic acid, Mp 10000Catalog Number 26167 -

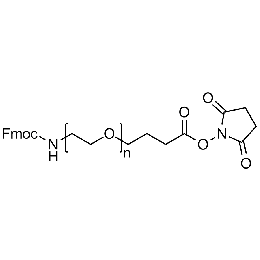

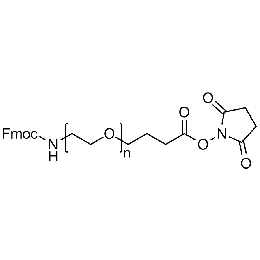

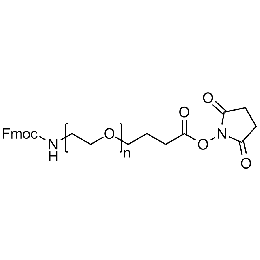

Fmoc-amine PEG NHS, Mp 3000Catalog Number 26168

Fmoc-amine PEG NHS, Mp 3000Catalog Number 26168 -

Fmoc-amine PEG NHS, Mp 5000Catalog Number 26169

Fmoc-amine PEG NHS, Mp 5000Catalog Number 26169 -

Fmoc-amine PEG NHS, Mp 10000Catalog Number 26170

Fmoc-amine PEG NHS, Mp 10000Catalog Number 26170 -

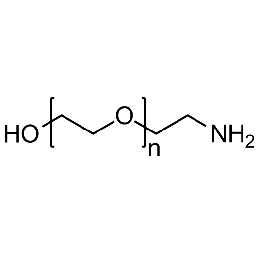

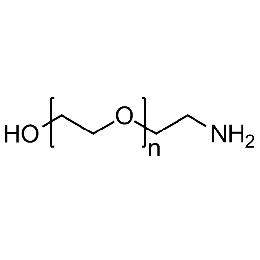

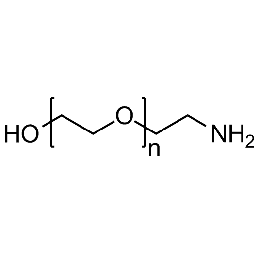

Hydroxyl PEG amine, Mp 3000Catalog Number 26171

Hydroxyl PEG amine, Mp 3000Catalog Number 26171 -

Hydroxyl PEG amine, Mp 5000Catalog Number 26172

Hydroxyl PEG amine, Mp 5000Catalog Number 26172 -

Hydroxyl PEG amine, Mp 10000Catalog Number 26173

Hydroxyl PEG amine, Mp 10000Catalog Number 26173 -

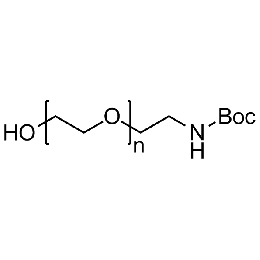

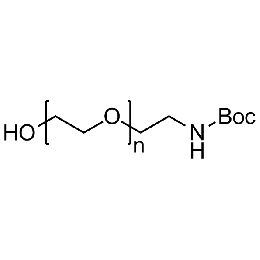

Hydroxyl PEG boc-amine, Mp 3000Catalog Number 26174

Hydroxyl PEG boc-amine, Mp 3000Catalog Number 26174 -

Hydroxyl PEG boc-amine, Mp 5000Catalog Number 26175

Hydroxyl PEG boc-amine, Mp 5000Catalog Number 26175 -

Hydroxyl PEG boc-amine, Mp 10000Catalog Number 26176

Hydroxyl PEG boc-amine, Mp 10000Catalog Number 26176 -

Hydroxyl PEG Boc-hydrazine, Mp 3000Catalog Number 26177

Hydroxyl PEG Boc-hydrazine, Mp 3000Catalog Number 26177 -

Hydroxyl PEG Boc-hydrazine, Mp 5000Catalog Number 26178

Hydroxyl PEG Boc-hydrazine, Mp 5000Catalog Number 26178 -

Hydroxyl PEG Boc-hydrazine, Mp 10000Catalog Number 26179

Hydroxyl PEG Boc-hydrazine, Mp 10000Catalog Number 26179 -

Hydroxyl PEG carboxylic acid, Mp 3000Catalog Number 26180

Hydroxyl PEG carboxylic acid, Mp 3000Catalog Number 26180 -

Hydroxyl PEG carboxylic acid, Mp 5000Catalog Number 26181

Hydroxyl PEG carboxylic acid, Mp 5000Catalog Number 26181 -

Hydroxyl PEG carboxylic acid, Mp 10000Catalog Number 26182

Hydroxyl PEG carboxylic acid, Mp 10000Catalog Number 26182 -

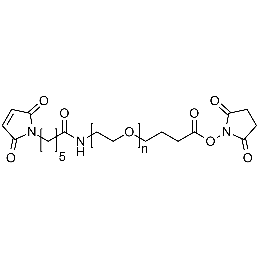

Maleimide PEG NHS, MP 10,000Catalog Number 26207

Maleimide PEG NHS, MP 10,000Catalog Number 26207 -

Hydroxyl PEG thiol, Mp 3000Catalog Number 26183

Hydroxyl PEG thiol, Mp 3000Catalog Number 26183 -

Hydroxyl PEG thiol, Mp 5000Catalog Number 26184

Hydroxyl PEG thiol, Mp 5000Catalog Number 26184 -

Hydroxyl PEG thiol, Mp 10000Catalog Number 26185

Hydroxyl PEG thiol, Mp 10000Catalog Number 26185 -

Hydroxyl PEG tritylthiol, Mp 3000Catalog Number 26186

Hydroxyl PEG tritylthiol, Mp 3000Catalog Number 26186 -

Hydroxyl PEG tritylthiol, Mp 5000Catalog Number 26187

Hydroxyl PEG tritylthiol, Mp 5000Catalog Number 26187 -

Hydroxyl PEG tritylthiol, Mp 10000Catalog Number 26188

Hydroxyl PEG tritylthiol, Mp 10000Catalog Number 26188 -

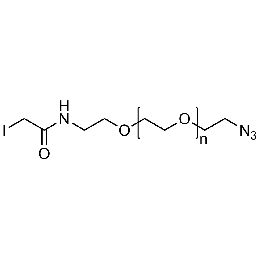

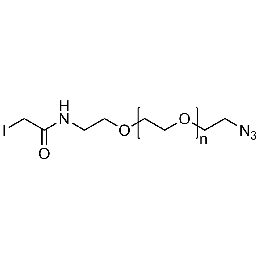

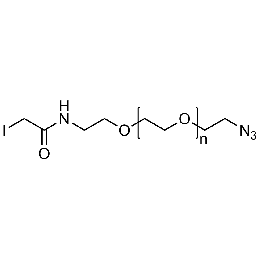

Iodoacetamide PEG azide, Mp 3000Catalog Number 26189

Iodoacetamide PEG azide, Mp 3000Catalog Number 26189 -

Iodoacetamide PEG azide, Mp 5000Catalog Number 26190

Iodoacetamide PEG azide, Mp 5000Catalog Number 26190 -

Iodoacetamide PEG azide, Mp 10000Catalog Number 26191

Iodoacetamide PEG azide, Mp 10000Catalog Number 26191 -

Iodoacetamide PEG azide, Mp 20000Catalog Number 26192

Iodoacetamide PEG azide, Mp 20000Catalog Number 26192 -

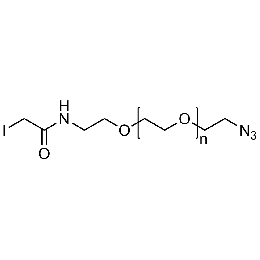

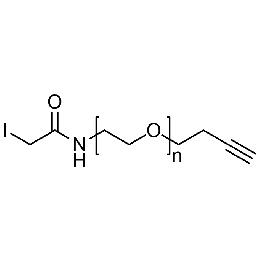

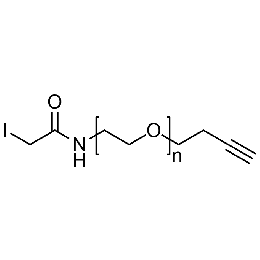

Iodoacetamide PEG alkyne, Mp 3000Catalog Number 26193

Iodoacetamide PEG alkyne, Mp 3000Catalog Number 26193 -

Iodoacetamide PEG alkyne, Mp 5000Catalog Number 26194

Iodoacetamide PEG alkyne, Mp 5000Catalog Number 26194 -

Iodoacetamide PEG alkyne, Mp 10000Catalog Number 26195

Iodoacetamide PEG alkyne, Mp 10000Catalog Number 26195 -

Iodoacetamide PEG alkyne, Mp 20000Catalog Number 26196

Iodoacetamide PEG alkyne, Mp 20000Catalog Number 26196 -

Maleimide PEG biotin, Mp 3000Catalog Number 26199

Maleimide PEG biotin, Mp 3000Catalog Number 26199 -

Maleimide PEG biotin, Mp 5000Catalog Number 26200

Maleimide PEG biotin, Mp 5000Catalog Number 26200 -

Maleimide PEG biotin, Mp 10000Catalog Number 26201

Maleimide PEG biotin, Mp 10000Catalog Number 26201 -

Maleimide PEG carboxylic acid, Mp 3000Catalog Number 26202

Maleimide PEG carboxylic acid, Mp 3000Catalog Number 26202 -

Maleimide PEG carboxylic acid, Mp 5000Catalog Number 26203

Maleimide PEG carboxylic acid, Mp 5000Catalog Number 26203 -

Maleimide PEG carboxylic acid, Mp 10000Catalog Number 26204

Maleimide PEG carboxylic acid, Mp 10000Catalog Number 26204 -

Maleimide PEG NHS, Mp 3000Catalog Number 26205

Maleimide PEG NHS, Mp 3000Catalog Number 26205 -

Maleimide PEG NHS, Mp 5000Catalog Number 26206

Maleimide PEG NHS, Mp 5000Catalog Number 26206 -

NHS PEG OPSS, MP 10,000Catalog Number 26214

NHS PEG OPSS, MP 10,000Catalog Number 26214 -

Silane PEG alkyne, MP 3000Catalog Number 26228

Silane PEG alkyne, MP 3000Catalog Number 26228 -

Biotin PEG OPSS, MP 5,000Catalog Number 26209

Biotin PEG OPSS, MP 5,000Catalog Number 26209 -

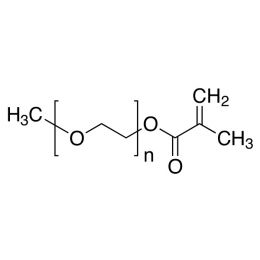

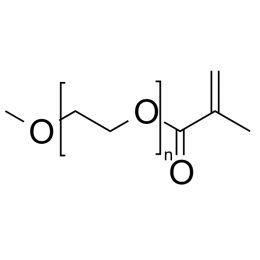

Poly(ethylene glycol) methylether acrylate, MW 10000 (mPEG-Ac 10K)Catalog Number 26277

Poly(ethylene glycol) methylether acrylate, MW 10000 (mPEG-Ac 10K)Catalog Number 26277 -

Poly(ethylene glycol) methylether methacrylate (mPEG-MAc 10K)Catalog Number 26278

Poly(ethylene glycol) methylether methacrylate (mPEG-MAc 10K)Catalog Number 26278 -

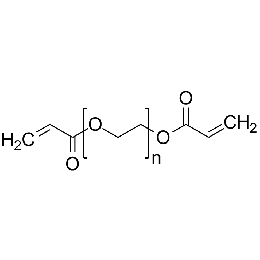

Poly(ethylene glycol) diacrylate, MW 10000 (PEGDA 10K)Catalog Number 26279

Poly(ethylene glycol) diacrylate, MW 10000 (PEGDA 10K)Catalog Number 26279 -

Poly(ethylene glycol) diacrylate, MW 20000 (PEGDA 20K)Catalog Number 26280

Poly(ethylene glycol) diacrylate, MW 20000 (PEGDA 20K)Catalog Number 26280 -

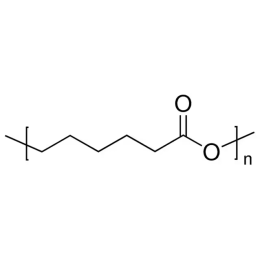

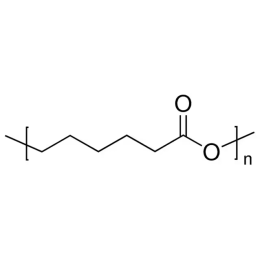

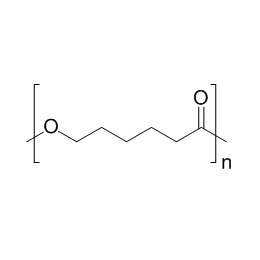

Polycaprolactone, MW 25000Catalog Number 26287

Polycaprolactone, MW 25000Catalog Number 26287 -

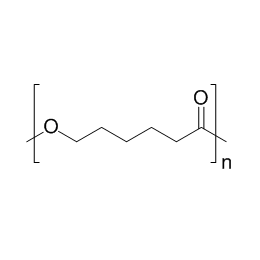

Polycaprolactone, MW 80000Catalog Number 26290

Polycaprolactone, MW 80000Catalog Number 26290 -

Ethylene glycol diglycidyl ether (EGDGE)Catalog Number 01479

Ethylene glycol diglycidyl ether (EGDGE)Catalog Number 01479 -

Ethylene Glycol Dimethacrylate, 99.7% (EGDMA)Catalog Number 24896High purity monomer for contact lens applications. Ethylene Glycol Dimethacrylate is useful as a high purity crosslinker with bridging/specialty capability between polymer chains.

Ethylene Glycol Dimethacrylate, 99.7% (EGDMA)Catalog Number 24896High purity monomer for contact lens applications. Ethylene Glycol Dimethacrylate is useful as a high purity crosslinker with bridging/specialty capability between polymer chains. -

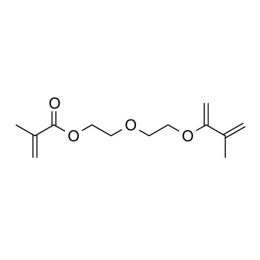

Diethylene glycol dimethacrylateCatalog Number 02214

Diethylene glycol dimethacrylateCatalog Number 02214 -

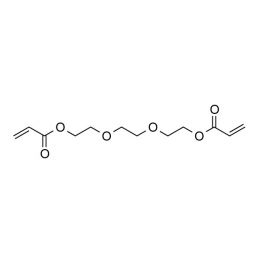

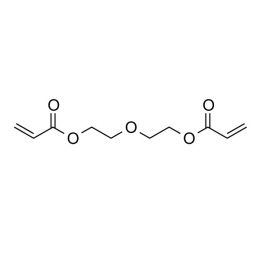

Triethylene glycol diacrylate (TriEGDA)Catalog Number 02655

Triethylene glycol diacrylate (TriEGDA)Catalog Number 02655 -

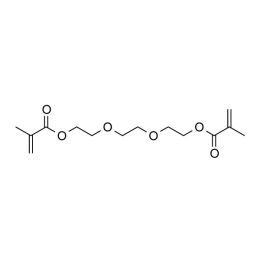

Triethylene glycol dimethacrylate, min 95%Catalog Number 24034

Triethylene glycol dimethacrylate, min 95%Catalog Number 24034 -

Poly(ethylene glycol) diglycidyl ether (PEGDGE 200)Catalog Number 08209

Poly(ethylene glycol) diglycidyl ether (PEGDGE 200)Catalog Number 08209 -

Polyethylene glycol diacrylate (PEGDA 400)Catalog Number 01871

Polyethylene glycol diacrylate (PEGDA 400)Catalog Number 01871 -

Poly(ethylene glycol) diglycidyl ether (PEGDGE 400)Catalog Number 08210

Poly(ethylene glycol) diglycidyl ether (PEGDGE 400)Catalog Number 08210 -

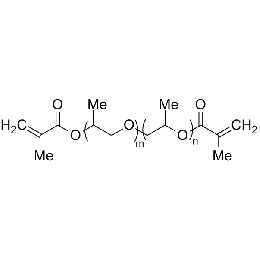

Poly(propylene glycol) (400) dimethacrylate (PPGDMA 400)Catalog Number 04380

Poly(propylene glycol) (400) dimethacrylate (PPGDMA 400)Catalog Number 04380 -

Polyethylene glycol monomethacrylate (PEGMA 440)Catalog Number 24890

Polyethylene glycol monomethacrylate (PEGMA 440)Catalog Number 24890 -

Poly(ethylene glycol) diglycidyl ether (PEGDGE 600)Catalog Number 08211

Poly(ethylene glycol) diglycidyl ether (PEGDGE 600)Catalog Number 08211 -

Polyethylene glycol dimethacrylate (PEGDMA 1000)Catalog Number 15178